OVERVIEW OF THE AL SHAMIYA EXPANSION PROJECT IN MAKKAH, SAUDI ARABIA:

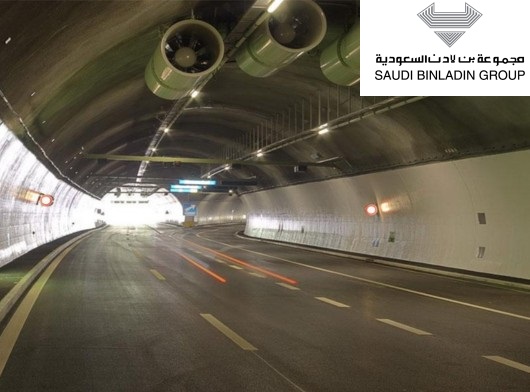

The Al Shamiya Expansion Project in Makkah, Saudi Arabia stands as a transformative endeavor aimed at reshaping the landscape and infrastructure of this revered city. With ambitious objectives and a comprehensive scope, this project holds the potential to not only enhance the local economy and community but also to set new standards for sustainable development. From infrastructure improvements to environmental considerations, the Al Shamiya Expansion Project is a crucial achievement in the continuous progress of Makkah and represents a significant development endeavor aimed at enhancing infrastructure, economic growth, and sustainability in the region. The implementation of the project includes the establishment of a new network of roads to enhance the pilgrimage experience. As a result, the Haram Mosque will have the capacity to accommodate four million pilgrims, which is four times its current capacity. The Al Shamiya Expansion Project aims to modernize Makkah's infrastructure, improve transportation systems, and enhance the overall quality of life for residents and pilgrims. This project will contribute to the city's sustainable growth and development. The Al Shamiya Expansion Project includes an underground tunnel infrastructure that provides efficient and direct routes, enhancing connectivity between communities. Niharika Computational Engineering Solutions Pvt Ltd (NCES) is honored to have been chosen for this significant project and are committed to delivering exceptional results.

CFD ANALYSIS TO OPTIMIZE TUNNEL VENTILATION SOLUTIONS

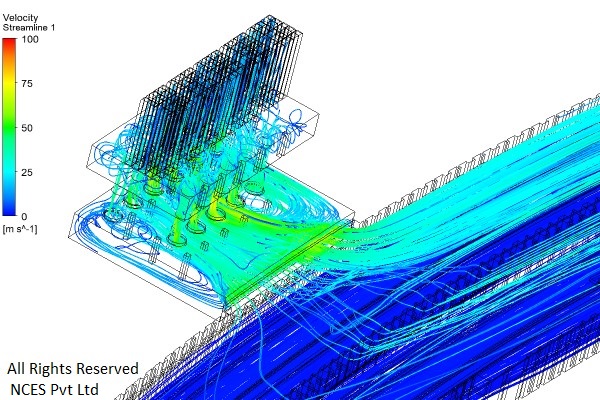

To ensure a safe and healthy environment within the tunnel, it is crucial to have a dependable ventilation system. This system will ensure a continuous supply of fresh air, minimizing the concentration of air pollutants during regular tunnel operations. Additionally, it will effectively extract smoke gases in case of emergencies. Utilizing Computational Fluid Dynamics (CFD) analysis for tunnel ventilation has become increasingly crucial in ensuring the safety, efficiency, and comfort of tunnel users. CFD analysis provides valuable insights into airflow patterns, temperature distribution, and pollutant dispersion within tunnels. Engineers can leverage these results to optimize ventilation strategies, such as adjusting fan placement or duct configurations, to enhance overall ventilation performance and user safety. By leveraging CFD simulations, stakeholders can make informed decisions that optimize airflow, minimize pollutants, and improve overall ventilation effectiveness. Our Computational Fluid Dynamics (CFD) simulation outcomes have allowed our client to comprehend the flow evolution within the entire tunnel and have faith in the suggested Jet fans and different operational configurations of motorized dampers for smoke extraction during emergencies. Our accurate HVAC CFD analysis results have empowered our client to make informed engineering choices for improved resource efficiency and safety adherence.

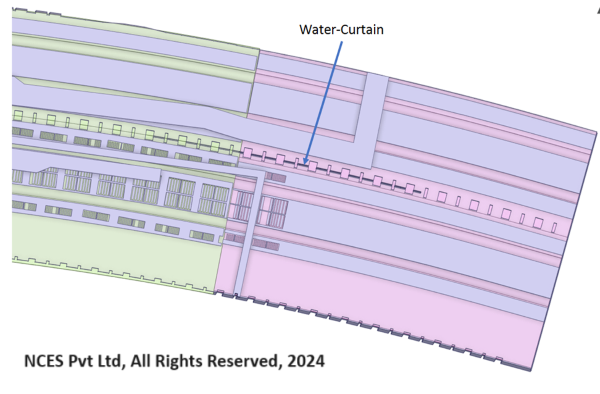

3D CAD MODEL DEVELOPMENT

test 3d cad model

CFD Mesh

test mesh

CFD Modelling

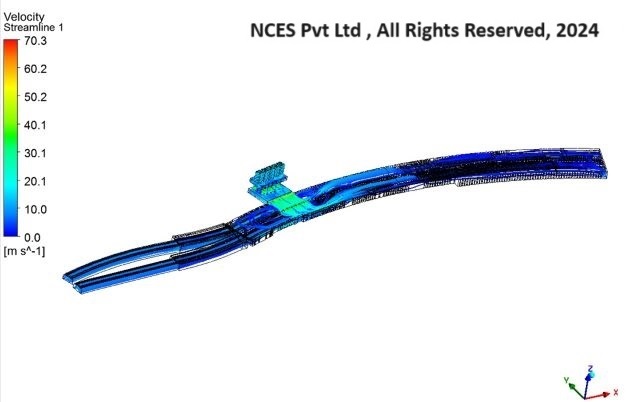

Overall Flow Development

test

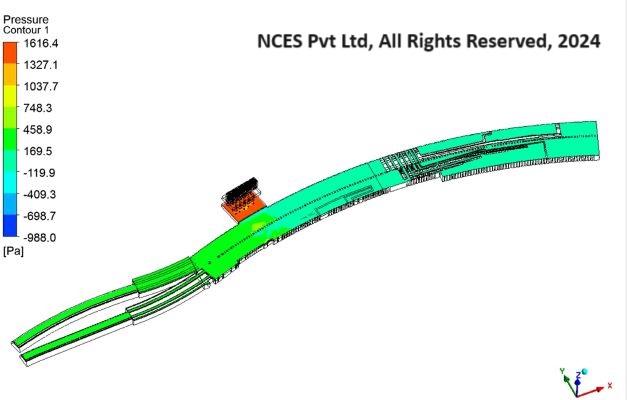

Pressure Field

test

Motorised dampers operation sequence

test

We Got More

Go through All Our Case Studies

CFD analysis to predict flow development in wind turbine blade mold facility (LM Wind Power, India)

We carried out CFD analysis for the HVAC Jet Nozzle system proposed in the Wind turbine blade molding division at the LM wind power blade manufacturing plant in Bangalore. The blade manufacturing plant consists of four molding bays; for each bay, cold air will be supplied through 2 AHU units. Each AHU unit is connected to 40 Jet Nozzles. The main objective of CFD analysis is to analyze airflow, air-impinging angle, and the flow regime. The flow regime plays a significant role from Health and safety perspective. We have explained our results to the Management of LM Wind power and recommended suggestions for Improvement. Read MoreCFD analysis for General Electric data center, Bihar, India

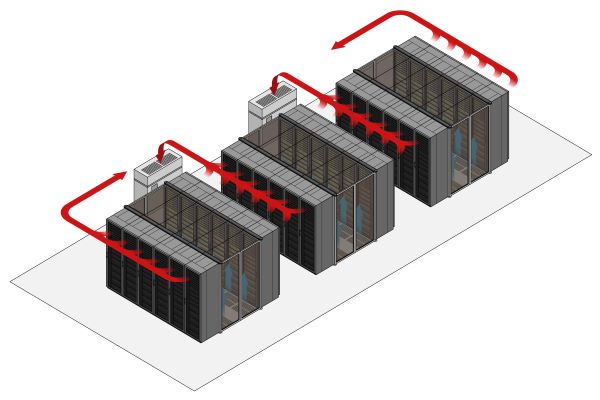

Computational Fluid Dynamics (CFD) analysis is extensively used in data center projects to study the flow development and temperature field and identify the thermal hot spots in the projects design stage. CFD analysis results enable the thermal designer to make well-informed decisions in the design stage and eliminate all the uncertainties that may affect the electronic equipment mounted in the racks. We carried out CFD analysis for the large data center under construction in the Bihar state of India by Shapoorji and Pallonji EPC company, one of the largest EPC Companies in India. Our CFD analysis results have enabled our customers to optimize the air-cooling system and ultimately to realize an efficient, safer, and effective data center cooling mechanism. Read MoreOptimization of hot and cold aisle rack/cabinet configuration in a data center using CFD analysis

The hot and cold aisles in the data center are part of an energy-efficient layout for server racks and other computing equipment. The goal of a hot/cold aisle configuration is to manage airflow in a way that conserves energy and lowers cooling costs. A containment system isolates hot and cold aisles from each other and prevents hot and cold air from mixing. Our client is executing a turnkey contract for a bank data center in Kuwait. We worked with our client from the beginning stage of the project and assisted them with our Computational Fluid Dynamics (CFD) analysis results. Our CFD analysis results have enabled our client to arrive at the best operating sequence of the cooling units. Read MoreCFD analysis for Car parking zone: Department of Finance, Government of India, Kerala

The scope of the work is to conduct Computational Fluid Dynamics (CFD) analysis for the basement car parking zone and ground floor of the Income-tax commissioner office in Kerala state, India. The objective of the CFD analysis is to finalize the location of Jet fans. We developed a 3D CAD model based on the layout drawings provided by our client. CFD mesh consists of 15 million polyhedral cells. CFD analysis results have enabled our client to identify the optimum location for Jet fans. We repeated the CFD analysis for various locations of the Jet fans, and the most efficient location is suggested. Read MoreCFD analysis to assess the proposed HVAC design: Satellite Integration clean room, Indian Space Research Organization, India

Air is the primary carrier of particulates and contaminants from their sources to air return locations in the cleanrooms employed by Industries like semiconductors, Medical devices, pharmaceuticals, and Satellite Integration. Proper airflow distribution is essential to ensure the desired level of cleanliness related to a class of the cleanroom. Depending on the level of cleanliness, the required airflow rates vary from a few to a few hundred air changes per hour (ACH). Maintaining a single-pass air flow path from the supply to the return location is highly desirable without significant recirculation and mixing. Our expertise and decades of experience in CFD analysis shall help our clients to optimize the performance of Semiconductor, Medical devices, Pharmaceutical, and Satellite Integration clean rooms. Read More