Empowering Sustainable Future With CFD and FEM Solutions for Energy

Our transformative engineering solutions employing niche digital engineering technologies like Computational Fluid Dynamics (CFD) analysis, Structural (FEM) analysis, and Computer-aided design have enabled global EPC contracting companies to make conscious engineering decisions to achieve sustainability, operational excellence, optimal utilization of resources, and to comply with safety standards.

Our engineering expertise and customer-centric work culture have enabled us to successfully execute projects belonging to global companies, including SABIC, Saudi Aramco, Saudi Royal Commission, Saudi Kayan, and Saudi Binladin group in collaboration with leading EPC contractors.

Innovative Engineering Solutions for Energy and Infrastructure EPC Industry

CFD Analysis and CAE Simulations for Energy, Petroleum, Chemical Infrastructure Upgradations, Tunnel ventilation, Fire propagation, and smoke evacuation.

Energy and Infrastructure is one of the significant Industry verticals in which we have successfully executed projects for major players like Sabic, National Methanol Company, Jubail United Petrochemical Company, and Saudi European Petrochemical Company.

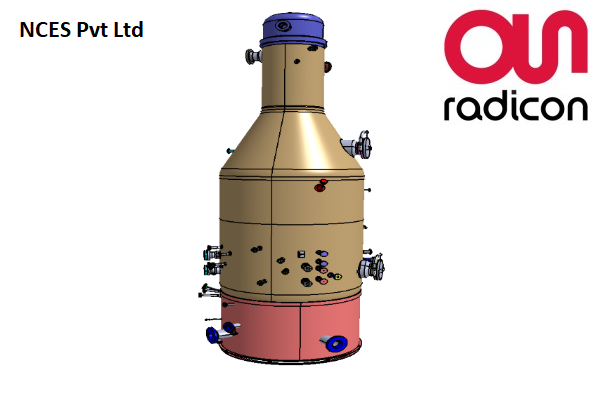

We helped our clients with critical tasks like the upgradation of petrochemical reactors, pollution control in Industrial Chimneys, Upgradation of chemical agitator units, Root cause investigation and remedial measures to address the deterioration in underground gas ducts, and vibration control of petrochemical transport lines.

Our Computational Fluid Dynamics (CFD) analysis solutions have enabled our clients to analyze various flows covering Ventilation, fire propagation, and smoke extraction in basement parking zones, underground tunnels, airports, and other public Infrastructure.

Our Structural analysis (FEA) capabilities have enabled our client to assess the complete structural Integrity of their engineering system.

Single & Multiphase Separator CFD analysis

Mixer and Agitator CFD analysis

Pollutant dispersion CFD analysis

Thermal analysis of underground ducts

Pressure vessels CFD and thermal analysis

Reactive and non-reactive flow in chemical reactors and boilers

Fire propagation studies

Fluid sloshing analysis

Flow assurance studies

Smoke propagation studies in basements & underground tunnels

Oxygen concentration studies

Stress analysis in piping

Static and dynamic analysis

Non-linear FEM analysis

Seismic and Vibration analysis

FEA for Pressure Vessel and Internals

Reverse Engineering

Concept Design

Sheet Metal Design

Chamber design

CAD Migration

Creo Services

UG-NX Services

2D to 3D Conversion

2D to 3D Modeling

Vector to Raster

Mechanical, Flow-Induced Vibration

Mechanical Overload

Fatigue failures

System–Component Interaction

Design Limitations

Thermal Distortion – Stresses

Improper Material Selection

Non-uniform Thermal Loading

Defects in Manufacturing

Defects in Heat transfer

CFD analysis of pollutant dispersion in Industrial Chimney: SABIC Group, Saudi Arabia

CFD studies- Pollutant concentration dilution in an Industrial chimney by steam Injection: SABIC Group, Saudi Arabia

Thermal analysis of underground hot gas duct with refractory lining: SABIC Group, Saudi Arabia

Two Phase Flow: Simulation of Oil Recovery with Water Injection, Leading EPC contracting company, Saudi Arabia

Accidental Release of LPG from Underground Pipe-CFD analysis to assist Emergency Response System, Leading EPC contracting company, Saudi Arabia

CFD analysis of Non-reactive flow in Polymerization reactor: SABIC Group, Saudi Arabia

CFD analysis for underground transport tunnel: Al Shamiya Expansion Project, Makkah, Saudi Arabia

Structural Integrity analysis of Industrial Chimney: SABIC Group, Saudi Arabia

Structural design and Optimization of disk baffle for polymerization reactor: SABIC Group, Saudi Arabia

Structural analysis of waste heat boiler stack: SABIC Group, Saudi Arabia

Static Structural analysis of jacket closure ring – Sulphur condenser: KNPC, Kuwait

Static structural and dynamic analysis of crude oil storage tank, Adani Petrochemicals, India

Static and dynamic analysis for blast furnace slag grinding unit shaft assembly, JSW Cement, India

3D CAD modeling of underground transport tunnel and Fan room: Al Shamiya Expansion Project, Makkah, Saudi Arabia

3D CAD modeling of disk baffle unit for polymerization reactor, Sabic affiliate, Saudi Arabia

3D CAD modeling of Industrial chimney and sparger unit, Sabic affiliate company, Saudi Arabia

3D CAD modeling of Oligomerisation reactor, Sabic affiliate company, Saudi Arabia

3D CAD modeling of the crude oil storage tank, Adani Petrochemicals, India

3D CAD modeling of Boubyan bank data center, Kuwait

3D CAD modeling of underground gas transport duct, Sabic affiliate company, Saudi Arabia

3D CAD modeling of melting furnace, TATA Steel, India

3D CAD modeling of blast furnace slag grinding unit shaft assembly, JSW Cement, India

Failure analysis of Flange weld socket Assembly Crack at Steel Flange – pipe weld during N2 flow: SABIC Group, Saudi Arabia

Failure analysis of centrifugal blower blades in high-temperature gas transport duct, DRDO, India

Study of high vibration in product transfer lines of a Petrochemical plant: SABIC Group, Saudi Arabia

Download Brochure

Client Speak

Case Studies

Looking for specialised CFD Analysis & CAE Simulation services? drop a message

Mechanical and Structural design of Disk baffle for Oligomerisation reactor

Read More

Pollution dispersion studies for SABIC chemical plant stack using Computational Fluid Dynamics (CFD)

Read More

CFD analysis of Helical Agitator

Read More

Cement grinding plant Roller shaft re-design and FEM analysis

Read More

Structural analysis of crude oil storage tank

Read More