The importance of mechanical engineering design in the areas of innovation and product creation cannot be overstated. Mechanical engineering design services are essential to determining how sophisticated equipment or consumer products will turn out. That is why we are going to discuss the relevance of these services in the product development process in this post, emphasising their value and bearing on the final product.

What Is Mechanical Engineering Design?

The construction and development of mechanical systems, components, and products are the focus of a wide variety of operations known as mechanical engineering design services. These services are crucial for turning abstract concepts into real, useful, and effective goods. In order to create solutions that satisfy particular demands, mechanical engineering design uses a combination of science, mathematics, imagination, and pragmatism.

Conceptualization and Ideation

Any journey of the product starts with an idea, and the development of these early concepts through mechanical engineering design is crucial. To transform abstract concepts into particular design requirements, engineers in this profession collaborate closely with product designers and innovators. To determine if the product concept is workable and has the potential for success, they take into account elements including functionality, performance, safety, and cost-effectiveness.

Detailed Design and Prototyping

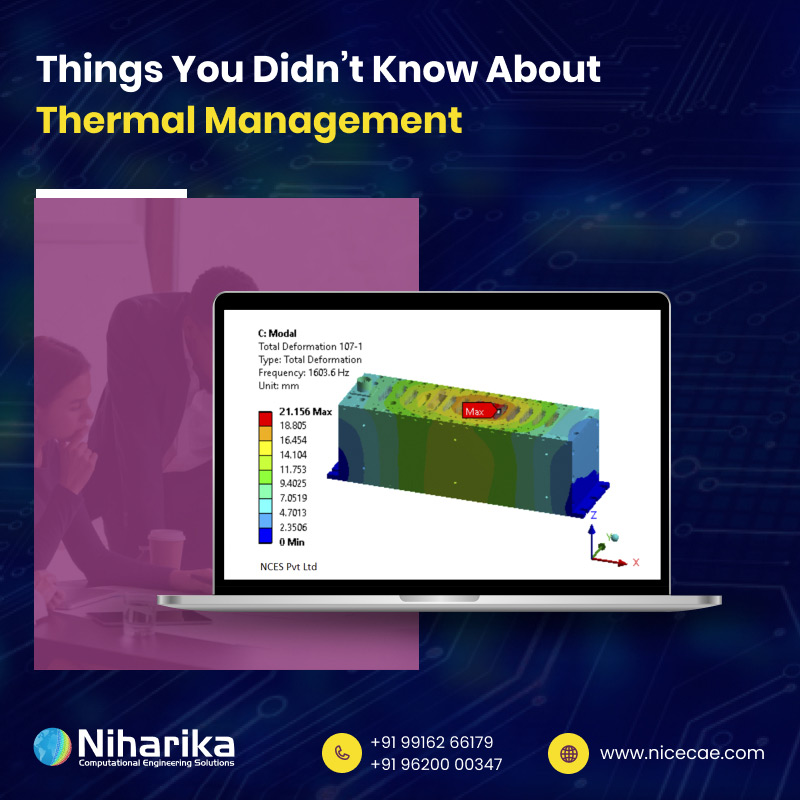

Mechanical engineers begin the thorough design step as soon as the concept is finalised. For each component of the product, detailed designs and specifications must be created. Modelling and simulating the behaviour of the product under different situations is frequently done using sophisticated software tools like CAD (Computer-Aided Design). This process enables engineers to find and fix any problems before the actual prototype is constructed.

A key component of mechanical engineering design is prototyping. It entails the construction of actual product models or prototypes. Engineers may test and evaluate their notions using these prototypes as physical representations of the design. At this point, any defects or inefficiencies may be found and fixed, saving time and money later on.

Material Selection and Manufacturing Processes

The correct materials must be chosen in order to manufacture the product, and mechanical engineers are crucial to this process. The choice of materials has a direct influence on elements including performance, cost, weight, and durability. To make sure that the chosen materials are compatible with the intended use and lifespan of the product, engineers take into account elements like material strength, thermal characteristics, and corrosion resistance.

The best production procedures for producing the product efficiently and affordably are also determined as part of the mechanical engineering design services. To optimise the production process, engineers consider elements like mass production, machining, or additive manufacturing.

Performance Optimisation and Testing

Mechanical engineering designs are iterative, so they are continuously improved and optimised to enhance product performance. To assess how the product performs in actual use, engineers conduct testing and simulations. They examine thermal behaviour, stress areas to ensure that the product complies with safety requirements.

Calculating costs and maximising value

Cost factors are essential to any success of the product. Mechanical engineers use cost analysis and value engineering to find areas where costs may be cut without sacrificing the quality or performance of the final product. To do this, every component and production step must be carefully examined to uncover more affordable options.

Final Thoughts

Mechanical engineering design services serve as the foundation upon which innovation flourishes in the always-changing world of product development. These services are crucial in determining how a product turns out, from the very beginning of ideation through the very end of manufacture. They help ideas become practical, successful, and affordable goods by bridging the gap between fantasy and reality.

It is impossible to emphasise the importance of mechanical engineering design services in the creation of new products. They are the driving force behind turning concepts into workable solutions. Mechanical engineers play a crucial role in influencing the innovation world by providing a methodical and comprehensive approach to product design and development. It is crucial to understand the significance that mechanical engineering design services play in obtaining success while attempting to bring a product to market.

.jpg)

.jpg)