In an age where challenges are unavoidable, the capacity to recognise the core causes of problems and implement effective remedies is critical. This is where root cause analysis services come into play. RCA is a methodology used in a variety of industries to identify the underlying causes of issues, and today we will go into the principles of root cause analysis, with an emphasis on the significance of root cause analysis services.

What Is Root Cause Analysis?

Root cause analysis is a systematic problem-solving strategy that extends beyond addressing symptoms to find the underlying causes of a problem. It is like peeling the layers of an onion in order to get to the centre. Organisations may use RCA to make more informed decisions, minimise the likelihood of issue recurrence, and ultimately enhance processes and results.

The RCA Procedure

The following steps are often included in the root cause analysis process:

Identifying the Problem: The first step is to precisely characterise the problem. What are the symptoms, and how do they affect you? This step is critical to ensuring that the correct issue gets handled.

Data Collection: In order to conduct a full analysis, relevant data must be gathered. Incident reports, performance indicators, and any other material that sheds light on the problem may be included.

Putting Together a Team: A multidisciplinary team is put together to add multiple viewpoints to the research. This diversity of ideas frequently leads to more robust outcomes.

Fishbone Diagram (Ishikawa): The fishbone diagram is a typical tool in RCA. It aids in the visualisation of the numerous components that may contribute to the problem, such as people, processes, equipment, materials, and the environment.

5 Whys Analysis: Another well-known approach is the "5 Whys." It entails continuously asking "Why?" to go deeper into the root causes of the problem. This iterative technique aids in the discovery of root causes by tracing problems back to their roots.

Identifying Fundamental Causes: The team can discover the fundamental causes of the problem after extensive study. These are the elements that, if addressed, would keep the problem from reoccurring.

Creating Solutions: After determining the fundamental reasons, the team may brainstorm and provide solutions. These solutions must be practical and successful in resolving the challenges indicated.

Implementing Solutions: The chosen solutions are put into action, and their effectiveness is monitored.

Monitoring and Recurrence Prevention: Continuous monitoring verifies the efficiency of adopted remedies and guarantees that the problem does not reoccur.

Why Root Cause Analysis Services Are Important?

Root cause analysis is a strong tool, and its potential is maximised when handled by specialised root cause analysis services. Here are some of the reasons why these services are so valuable:

Expertise: Root cause analysis services employ individuals with specialised expertise and problem-solving experience. They provide a new viewpoint on complicated topics.

Efficiency: These services streamline the RCA process, making it more efficient and effective. This reduces disturbances in normal operations.

Objective Analysis: An objective analysis ensures an unbiased assessment of problems, lowering the likelihood of internal biases distorting the study.

Comprehensive Approach: Root cause analysis services might employ a variety of techniques and approaches. They may adjust their strategy to the problem of the organisation and the its demands.

Prevention Focus: Root cause analysis services are concerned not only with treating present difficulties but also with preventing their recurrence. This long-term approach may save businesses time and money in the long run.

Real-Life Applications

Root cause analysis services are used in a variety of sectors to solve a wide range of difficulties. Here are a couple such examples:

Manufacturing: RCA services aid in the identification of flaws in goods and processes, decreasing waste, and enhancing product quality.

Aerospace and Defense: RCA is used by the aerospace and defence sectors to look into safety events, equipment malfunctions, and aircraft accidents. This contributes to increased dependability and safety.

Design Failure: RCA can be used to look at product design flaws such manufacturing faults, problems choosing materials, or engineering mistakes. It assists in identifying the reasons behind a fa to fulfil anticipated functionality or performance requirements as well as the design adjustments required to address the problems.

Machine vibrations issue: Engineers can use RCA to analyse the complex interconnections and contributing elements that cause excessive vibrations. This may entail investigating not just mechanical problems, but also environmental conditions, operational practises, and other aspects.

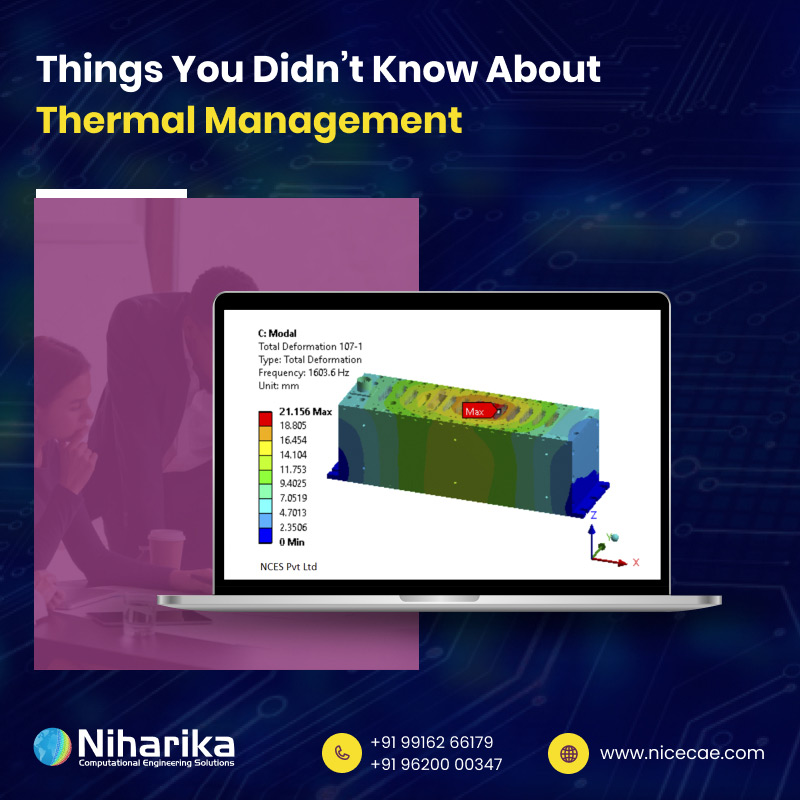

Thermal Challenges in HVAC and Electronic products:

Heat Generation

When HVAC systems run, heat is produced, especially when air conditioners and heat pumps are involved. If this heat is not well controlled, it may negatively impact the efficiency of the system. It is a natural result of electronic device functioning for computers, cellphones, and servers to produce heat. It gets harder to control heat dissipation as these gadgets get smaller and more powerful.

Cooling Efficiency

In hot temperatures, HVAC equipment, particularly air conditioners, might perform less effectively. When the outside temperature is high, controlling the air quality within a structure can be difficult. On the other hand, when running at high speeds, integrated circuits, CPUs, and other electronic components produce a lot of heat. Temperature controls are achieved by using liquid cooling solutions, fans, or efficient heat sinks.

Reliability

For HVAC systems to function as efficiently as possible, frequent maintenance is necessary. Refrigerant leakage and component overheating are examples of heat-related problems that can cause system malfunctions and downtime. The lifespan of electronic components can be shortened by high working temperatures. To guarantee the long-term dependability of electronic devices, it is imperative to maintain a consistent and cool operating temperature.

Final Thoughts

Root cause analysis is a strong problem-solving methodology that has the potential to revolutionise how organisations deal with difficulties. Understanding the principles of root cause analysis is critical, whether you work in manufacturing or any other field. When paired with the experience of root cause analysis services, it transforms into a powerful force for continuous development, preventing issues from arising and paving the path for a more efficient and effective future. Contact NCES today and embrace the power of RCA to realise your the full potential of the organisation.

.jpg)

.jpg)