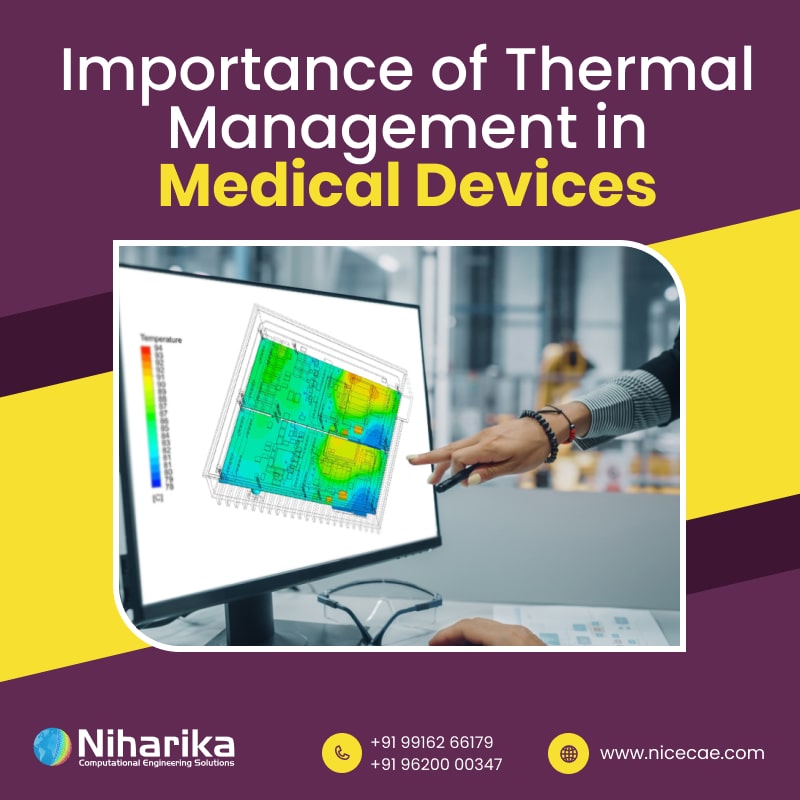

Medical devices are now essential instruments that improve patient care, diagnosis, and treatment in the fast-changing world of healthcare technology. Medical devices are pushing the limits of innovation, from the smallest wearable health monitors to the most sophisticated imaging instruments. But there is one important factor that is frequently disregarded: the thermal management solution. That is why we are going to explore the relevance of thermal management in medical devices and clarify why it is crucial for both manufacturers and healthcare professionals to take it into account.

Basics of Thermal Management

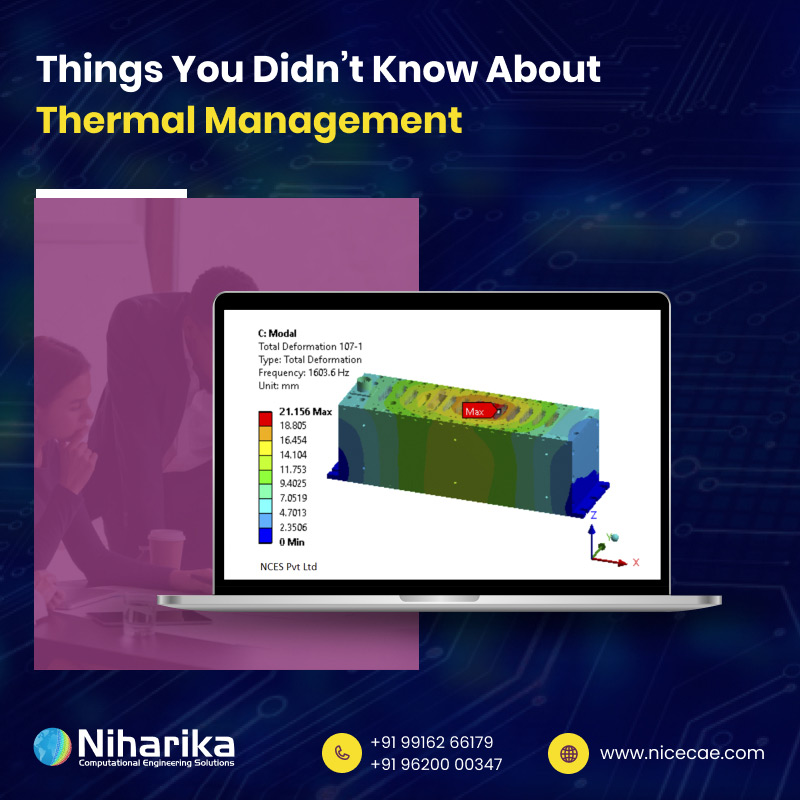

Before diving into the details, let us first understand the fundamental concepts of thermal management in medical devices. What is thermal management? The methods and procedures employed to control the heat produced by components of the electronic device are known as thermal management solutions. This heat can originate from a variety of components in medical equipment, such as microprocessors, power amplifiers, and sensors.

Importance of Thermal Management in Medical Devices

Patient Safety

Patient safety is one of the main considerations in the design of medical equipment. The precise measurement of physiological data is necessary for these devices to operate as intended. Sensors and transducers precision and dependability can be harmed by high temperatures. Any miscalculation can have fatal repercussions while providing critical care, such as when monitoring heart rate of the patient or oxygen levels. These sensors operate precisely thanks to efficient heat management, which lowers the possibility of incorrect diagnoses or treatments.

Device Longevity

It is common for medical equipment to be expected to work consistently for long periods of time. Premature parts failure brought on by overheating can be expensive to replace and raise doubts about the availability of the gadget in emergency situations. Medical gadgets live longer thanks to effective heat management, which also ensures that they continue to work as intended.

User Comfort

There are several medical instruments in close proximity to patients. User comfort is crucial for all devices, including imaging equipment and wearable health monitors. Burns, skin irritation, and pain can all result from excessive heat generation. When patients are comfortable, they are more likely to adhere to prescribed therapies, and appropriate thermal management increases patient comfort.

Regulatory Compliance

To guarantee their efficacy and safety, medical devices must adhere to strict regulatory standards. Devices must meet a number of strict requirements of the regulatory agencies, including those set forth by the FDA in the United States. These criteria frequently include proper heat management, and manufacturers must show that their products comply in order to receive regulatory clearance.

Energy Efficiency

Energy-efficient medical equipment is in great demand as sustainability and energy conservation become more important. In addition to preventing overheating, an efficient thermal management solution lowers the energy consumption of equipment, making it more cost- and environmentally-friendly to use.

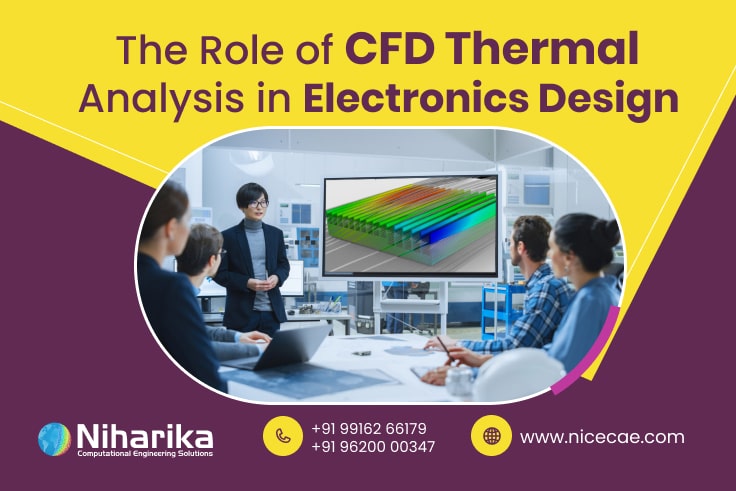

Innovations in Thermal Management

Irrespective of the challenges, there have been outstanding advancements in the field of thermal management in medical devices:

• Advanced cooling Technologies

Engineers are investigating cutting-edge cooling techniques, including microfluidic cooling, which provides effective heat dissipation in small places without the need for obtrusive fans.

• Smart Thermal Management

Thermal management solution is optimised in real-time using artificial intelligence and machine learning algorithms, ensuring that devices function at the appropriate temperature under a variety of circumstances.

• Material Innovation

New materials are being developed with higher thermal conductivity qualities, enabling more effective heat transport and dissipation.

• Miniaturisation

Recent developments in miniaturisation allow for the direct integration of heat management strategies into the components of the device, reducing the total footprint.

Final Thoughts

In the world of medical devices, thermal management is a crucial factor that has a direct bearing on patient safety, device longevity, and overall healthcare results. Manufacturers must give top priority to efficient heat management techniques while taking into account the special difficulties associated with medical applications.

The value of thermal management solutions will only grow as there is a larger need for modern medical technology. It connects the latest developments in technology and patient care, ensuring that medical equipment offers the required benefits in a safe and effective manner. In an industry where healthcare innovation never stops, keeping it cool is not just a choice but a necessity.

.jpg)

.jpg)