Data center CFD analysis services that enhance Cooling Solutions and energy efficiency

Data center CFD analysis services employ Computational Fluid Dynamics software to model and enhance airflow, temperature regulation, and cooling systems within data centers. These services facilitate the evaluation of airflow management and cooling effectiveness, pinpoint hot spots, and refine containment strategies, resulting in greater efficiency and reliability.

Benefits of Data Center CFD analysis services

Improved efficiency

Enhancing airflow and cooling through CFD analysis can result in decreased energy usage and reduced operational expenses

Enhanced Reliability

Identifying and addressing potential issues with airflow and temperature can improve the reliability of data center operations

Risk Mitigation

CFD simulations can help identify and mitigate potential risks, such as hot spots or airflow disruptions

Cost savings

By optimizing design and operations, CFD analysis can help reduce construction costs and long-term operational expenses

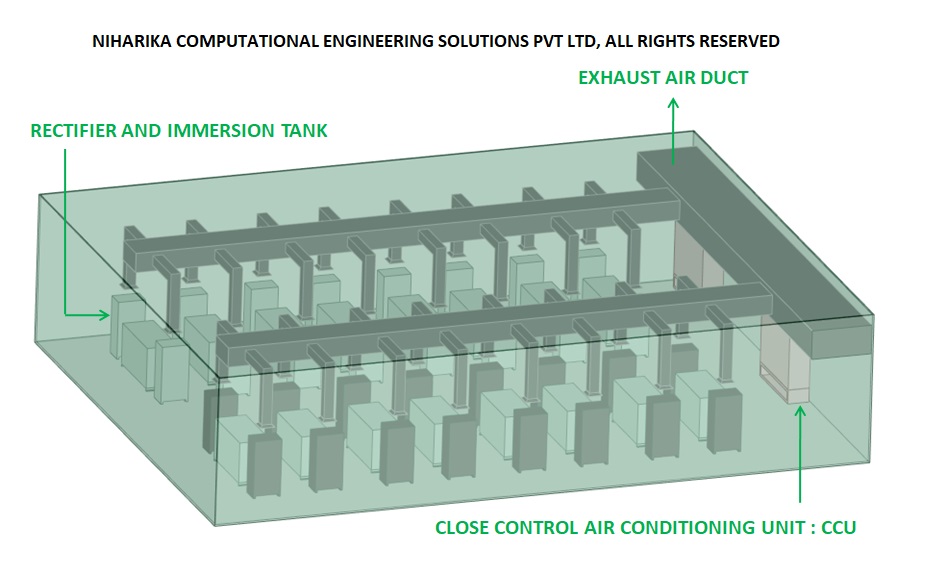

Data hall CFD analysis

In the demanding realm of data centers, where critical servers produce significant heat, the implementation of effective cooling systems is essential. At NCES, we utilize Computational Fluid Dynamics (CFD) to design and enhance HVAC (Heating, Ventilation, and Air Conditioning) systems, ensuring that your data center operations benefit from efficient and dependable cooling solutions. Our CFD analysis is vital for simulating and modeling the environments within data centers, thereby improving the performance of cooling systems. Through detailed simulations, we analyze air velocity and temperature distributions in data halls, allowing us to pinpoint potential hot spots and refine cooling strategies to avert equipment overheating. Our expertise is not limited to the initial design phase. NCES also performs comprehensive evaluations of existing HVAC systems under increased operational loads. This assessment determines the additional load capacity of the current system and offers practical recommendations for optimizing cooling configurations to support future growth.

External yard: Flue gas dispersion analysis

In data centers, the external yard that accommodates essential equipment such as generators, chillers, and FAHUs is critical to the overall functionality of operations. It is imperative to understand how this equipment performs in relation to ambient conditions to guarantee both efficiency and safety. At NCES, we excel in performing thorough CFD (Computational Fluid Dynamics) analyses for external yards and flue gas dispersion. Our specialized knowledge enables designers to evaluate the environmental effects of pollutants released from equipment, including NOx, SOx, CO, CO2, particulate matter, and volatile organic compounds.We utilize CFD analysis to assess the performance of mechanical equipment, such as chillers and generators, by examining inlet temperatures and recirculation impacts. Our simulations replicate the equipments environment, taking into account surrounding structures and ambient conditions, to enhance performance and identify potential issues proactively. Our flue gas dispersion analysis entails developing intricate environmental models to forecast the patterns and concentrations of pollutant dispersion. By factoring in elements such as stack height, diameter, exit velocity, and pollutant levels, we deliver practical insights to reduce environmental impacts. Our analysis ensures adherence to the World Health Organization (WHO) Air Quality Guidelines and aids in the design of optimal stack configurations and mitigation strategies.

Mechanical and Electrical room analysis

In mechanical and electrical facilities, which encompass generators, transformers, low-voltage (LV) systems, and battery storage, it is vital to manage high heat loads to prevent equipment malfunctions and maintain operational reliability. Adequate ventilation is crucial for sustaining optimal temperatures and protecting sensitive machinery. At NCES, we employ sophisticated Computational Fluid Dynamics (CFD) modeling to develop ventilation strategies tailored for these high-heat settings. Our proficiency in CFD allows us to create precise models of mechanical and electrical rooms, incorporating detailed representations of both equipment and ventilation systems. This capability enables us to visualize airflow patterns and temperature distribution throughout the entire space, offering a thorough understanding of heat management and dissipation. Our CFD analysis includes simulations of both natural and forced ventilation systems, taking into account various elements such as heat loads, surface temperatures, and equipment layouts. By constructing detailed models of the room and its components, we evaluate the effectiveness of the current ventilation design and pinpoint areas that may require enhancement. After completing our CFD analysis, we deliver practical insights and recommendations aimed at optimizing ventilation. This may involve repositioning vents, introducing additional fans, or altering ductwork to ensure that room temperatures remain within acceptable limits. Our objective is to guarantee that the ventilation system effectively alleviates heat accumulation, safeguards essential equipment, and facilitates uninterrupted operations.