Optimise Indoor Environments With HVAC Analysis Services

Concerned about uneven temperature distribution, inefficient airflow, or energy wastage?

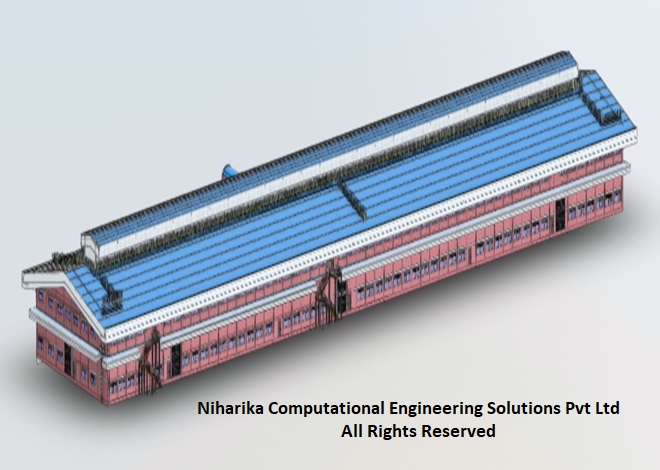

At Niharika Computational Engineering Solutions, we strive to provide the latest HVAC analysis services to improve indoor air quality, comfort, and energy use. Our expert engineers use advanced simulation techniques to analyze airflow, temperature levels, and how well ventilation works in many places, including offices and factories.

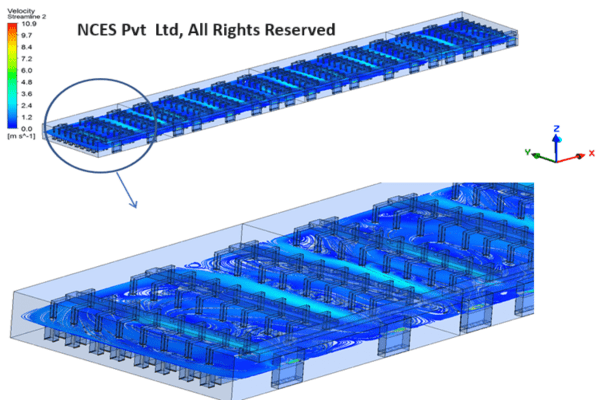

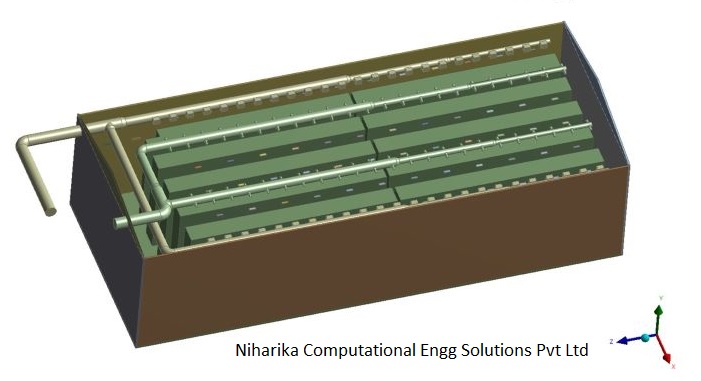

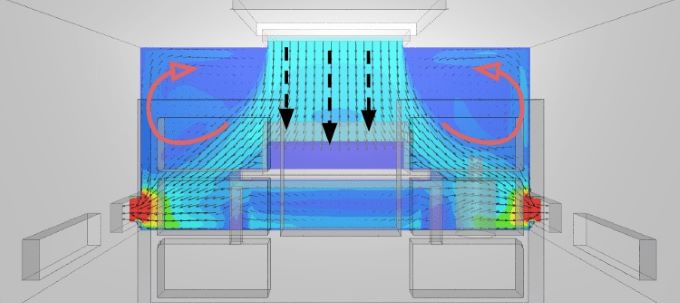

We examine the dynamics of your HVAC systems in-depth using cutting-edge Computational Fluid Dynamics (CFD) technologies to find hidden inefficiencies and improve performance. Our custom solutions tackle any issues you may be having, such as recurring hot spots, poor ventilation, or rising energy costs.

Why Choose Our HVAC CFD Analysis Services?

We are able to give clear and helpful analyses that fit the needs of your project. We help find problems, predict possible issues, and offer practical solutions that improve HVAC system performance. Whether we are creating a new system or making an old one better, our services aim to meet environmental goals, lower running costs, and follow the rules. .

We apply developed CFD tools that simulate real life, such as airflow, temperature differences, spread of contaminants, and pressure changes. The data-based method enables us to give recommendations that increase comfort levels for people and the efficiency of how they work.

• Utilization of Our Services

Our HVAC CFD analysis services are offered in several sectors, such as keeping offices at a consistent temperature and maintaining air quality in clean rooms and factories. Our solutions include thermal comfort analysis, smoke & evaluation analysis, car parking and tunnel ventilation analysis, and others. We focus on the best performance analysis at Niharika Computational Engineering Solutions. NCES is committed to excellence in HVAC performance analysis. Contact us today to learn how our CFD expertise can revolutionize your HVAC systems.

NCES, a prominent HVAC CFD Consultant in India, utilizes Computational Fluid Dynamics (CFD) analysis to enhance HVAC system designs during the initial stages. Effective HVAC design is essential for improving thermal comfort and managing operational expenses. Our HVAC CFD analysis services adhere to industry standards such as ANSI / ASHRAE 55, ISO 7730, EN 15251, and ISO 9920. Our team meticulously examines velocity, temperature, thermal radiation, and relative humidity profiles to guarantee a comfortable and healthy indoor environment. High-traffic locations like airports, shopping malls, hospitals, religious sites, and warehouses significantly benefit from our HVAC CFD analysis services during the design phase. With a proven history of successful projects for international clients, NCES has the expertise to apply CFD analysis across various contexts, helping to pinpoint the most effective design configurations. NCES is committed to creating sustainable, comfortable, and cost-effective building environments. By preventing costly over-design and enhancing energy efficiency, our CFD analysis empowers clients to achieve exceptional HVAC performance while maintaining high standards of indoor comfort and air quality.

NCES excels in assessing the effectiveness of Smoke Exhaust Systems through comprehensive Smoke Analysis in intricate structures such as airports, shopping malls, museums, and auditoriums, utilizing advanced CFD simulation techniques. Our team has significant expertise in Smoke and Evacuation Modelling, which is crucial for maintaining safety and operational efficiency in buildings during fire incidents. Our sophisticated simulation tools assist architects, fire safety engineers, and property owners in designing systems that safeguard occupants and assets by refining smoke control and evacuation strategies. We employ CFD software to analyze smoke dynamics across various building categories, including commercial, residential, and industrial facilities. Our smoke modeling services evaluate the behavior of smoke and heat in the event of a fire, allowing us to pinpoint potential risks and formulate effective mitigation plans. By forecasting smoke dispersion, temperature variations, and visibility conditions, we ensure compliance with rigorous safety standards and regulations. Our CFD analysis is conducted in accordance with both local and international standards, such as the UAE Fire and Life Safety Code, Saudi Fire Code (SFC), NFPA 92 for smoke control systems, NFPA 101 for life safety, SFPE guidelines, EN 12101-6 for Smoke & Heat Control Systems, ISO 16730, ISO 16733, and BS 7974, tailored to meet specific project needs. Additionally, our CFD analysis provides precise simulations of occupant movement and evacuation during emergencies, allowing us to enhance evacuation routes, reduce egress times, and improve overall safety protocols.

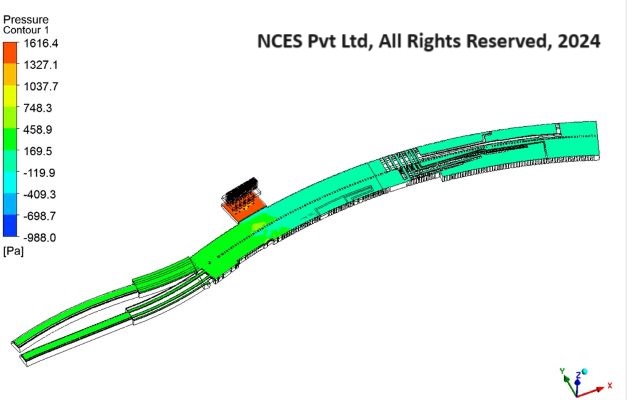

NCES has established a strong reputation for successfully managing projects focused on the design of advanced ventilation systems specifically for car parks and tunnels, with a strong emphasis on safety and compliance with international standards. Our expertise in Computational Fluid Dynamics (CFD) plays a crucial role in optimizing ventilation systems, particularly those that incorporate jet fan technology. Through our CFD assessments, we help clients determine the optimal number and placement of jet fans to maintain carbon monoxide (CO) levels within acceptable limits. By simulating different configurations, we enhance the positioning and orientation of jet fans to promote effective CO distribution and ensure adherence to regulatory standards. Once the jet fan configurations are optimized, we conduct a comprehensive fire analysis to comply with fire code requirements. This analysis evaluates critical tenability factors, including temperature, visibility, radiant heat flux, and CO concentrations in car parks and tunnels. Our approach ensures that emergency situations are managed effectively, prioritizing the safety of occupants and the integrity of the structure. With extensive experience working with international clients, NCES has built a solid reputation for delivering reliable and efficient solutions. Our standard ventilation CO analysis aligns with guidelines such as ASHRAE 16, California Standard 2019 CMC 403.7.2(2), Australian/New Zealand Standard AS1668.2-2012, and the Australian National Construction Code NCC2022. For smoke analysis, we comply with standards including BS 7346-7-2006, NFPA 92, NFPA 130, SFPE, NFPA 88A, EN 1991-1-2, as well as local regulations such as the UAE Fire and Life Safety Code, Qatar Fire Code, and Saudi Fire Code. This dedication ensures that our solutions meet stringent safety and performance criteria.