Hire Us for Top-Notch CFD Analysis and Consulting Services

With decreasing profits and increasing cost pressures, several manufacturers worldwide are favoring advanced product development tools to introduce products in the market that have competitive cost structures. NCES engineers have wide experience and knowledge in offering CFD analysis services across various industries. Our professionals are ready to help companies searching for the best practices in numerical simulations. Being one of the best CFD consulting services, we find ways to improve your product designs and manufacturing processes throughout your entire product development, product design or product improvement process. Our CFD consulting team can assist you in achieving the desired product performance and quality standards throughout your whole product development, product design, or product improvement process.

Revolutionize Your Designs with Our CFD Consulting Services

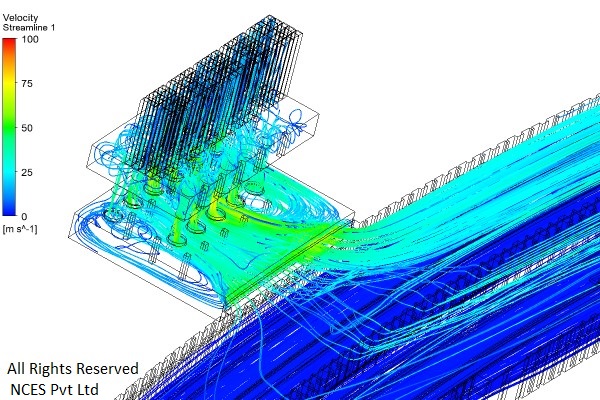

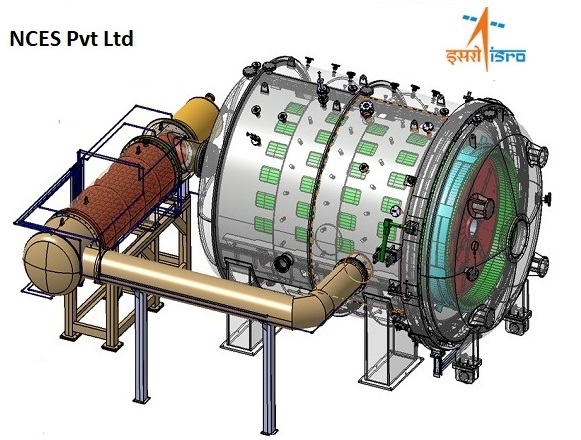

Our fluid dynamics expertise allows design engineers and manufacturers to analyze their products involving fluid flow, starting from the early design phase, with the use of cutting-edge hardware and software infrastructure facilities. Our team, which includes mechanical engineers, CFD analysts, and domain specialists, works together to provide manufacturers with cost-effective design solutions that will shorten their time to market.

With our CFD consulting services, you will be able to optimize your designs and systems virtually and lessen the need for costly physical prototypes and extensive testing, ultimately saving you time and money.

Our services are based on solving various analysis related challenges that companies encounter during product development. Since each project is different, we customize our CFD consulting services to fit your particular needs. Whether you require single-phase or multiphase analysis, steady-state or transient simulations, or both, we can help.

We provide a comprehensive range of Computational Fluid Dynamics (CFD) analysis services which enabled our customers to develop high quality engineered products and to strengthen their market position. Our CFD analysis capabilities includes,

Aerodynamics, Aerothermodynamics

test content