Benefits of Computational Fluid Dynamics (CFD) and Finite Elements Method (FEM) in Process Industries

In process Industries, Computational Fluid Dynamics (CFD) and the Finite Element Method (FEM) are used for simulation and analysis, offering significant advantages in design, optimization, and problem-solving. CFD focuses on fluid flow and heat transfer, aiding in tasks like optimizing reactor designs, studying mixing, and analyzing equipment performance. FEM, on the other hand, excels in structural analysis, predicting how products react to forces, vibrations, and heat, helping to refine designs and improve performance.

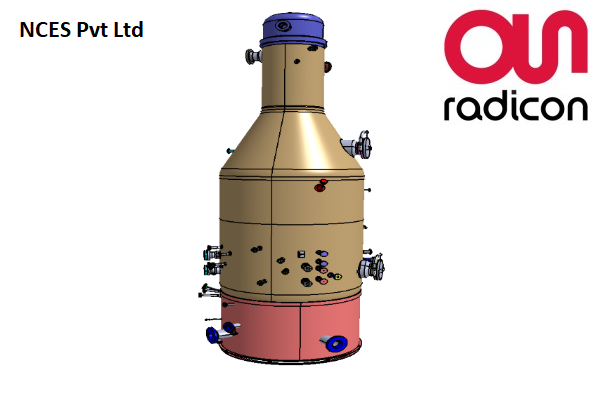

Benefits of CFD and FEM analysis in Process Industries