AGITATOR - AN OVERVIEW

Agitators are equipment used to homogenize media inside a tank. They work by rotating immersed impellers at a controlled speed. The work exerted by the impeller induces the flow and shear of the media inside the tank, causing a single or multi-component media to homogenize. Agitators are used in industries to enable proper mixing of liquids, promote chemical reactions inside the equipment, keep homogeneous liquid bulk during storage, increase heat transfer during heating or cooling, disperse immiscible liquids, keep the product in a mixed state until used, blend miscible liquids, and dissolve some solids into liquid. Common types of agitators employed for industrial purposes are Paddle Agitators, Anchor type agitators, Propeller type agitators, Blade type agitators, Turbine type agitators, and Helical Agitators. Helical agitators are a type of mixing equipment consisting of ribs or blades arranged in the form of a helix. This design creates axial motion and vigorous fluid motion inside a vessel. It is often used to mix viscous materials. The helical agitator is commonly used for low Reynolds number industrial mixing. The helical design of these agitators generates high shear rates and ensures thorough mixing of materials with different densities and viscosities. Helical agitators are used in polymer industries and other industries that require the use of quite viscous materials.

SCOPE OF THE PROJECT

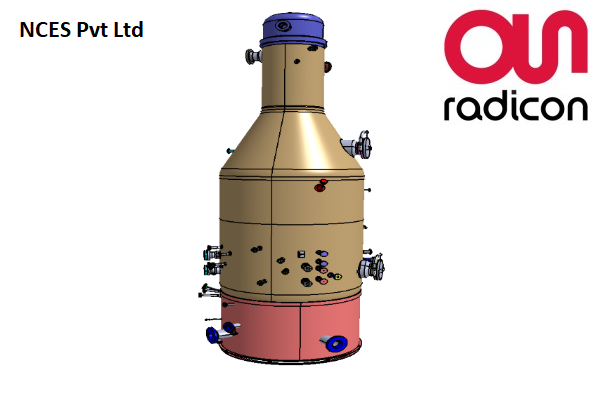

The objective of the project is to perform a 3D transient multiphase computational fluid dynamics (CFD) analysis for a helical agitator measuring approximately 12 meters in height and 3 meters in diameter. The helical coil is powered by a 30 HP motor operating at 24 RPM. The client seeks to understand the mixing process of three distinct types of polymer granules and the duration required to attain homogeneity in the mixture.

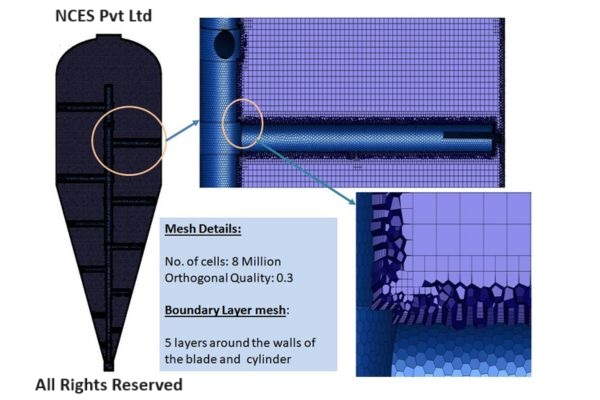

CFD MESH

The computational fluid dynamics (CFD) domain is discretized using polyhedral hex core elements, resulting in an approximate mesh count of 8 million. The mesh is specifically refined in areas with high flow gradients. Quality metrics for the mesh are upheld in accordance with established best practices in CFD analysis.

EULERIAN MULTIPHASE FLOW MODEL

The Eulerian computational fluid dynamics (CFD) model is utilized to simulate the transport of granules alongside the primary air phase, incorporating suitable interaction models for each phase. This model operates with a shared pressure field across all constituent phases, while the momentum and continuity equations are addressed independently for each phase. The Eulerian approach is particularly effective for examining the mixing of granules.

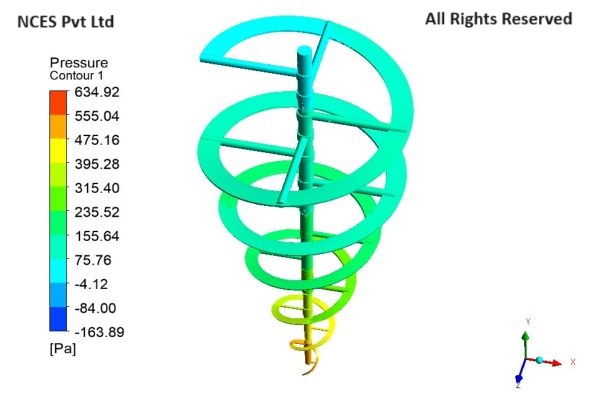

Pressure on the Helicoil

The pressure contours on the helicoil have been provided to the client for further finite element analysis studies. All species share a common pressure field in the Eulerian multiphase CFD analysis.

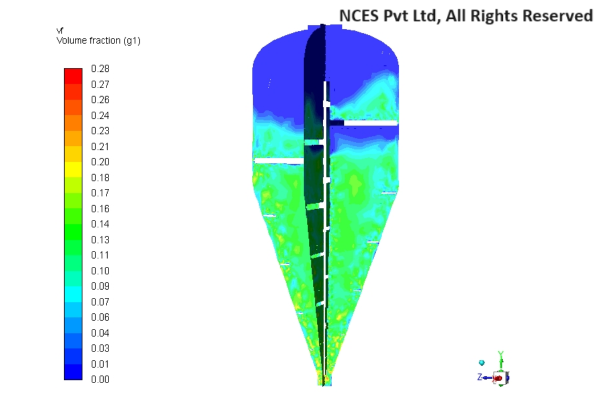

Volume Fraction

Contour plots and the graphical representation of the volume fraction for each species in a multiphase mixing CFD analysis demonstrate the efficiency of the agitation process. A thorough analysis of the volume fraction for each granular species at various heights of the agitator is conducted, leading to a comprehensive conclusion about the effectiveness of the mixing process.

We Got More

Go through All Our Case Studies

Mechanical and Structural design of Disk baffle for Oligomerisation reactor

We executed this project for a SABIC Petrochemical plant located in Al Jubail, Saudi Arabia. The proposed disk baffle is expected to serve the function of separating the condensate in the Oligomerisation reactor. We developed the conceptual model of the disk baffle using our expertise in core mechanical design and optimized the design using Finite Element Analysis (FEA). We provided detailed fabrication drawings to the customer and supported them during Fabrication process. Read MoreCFD analysis of anaerobic Bio digester-Multiphase flow CFD analysis

. Effective mixing within the digester promotes biological, chemical, and physical uniformity, preventing the creation of dead zones that hinder substrate conversion. Insufficient mixing can lead to reduced digester performance, while excessive mixing may disrupt the digestion process due to high shear forces. Therefore, it is essential to thoroughly understand and examine the optimal mixing techniques in anaerobic digesters. Read More

CFD Analysis of Regenerative Thermal Oxidizer

Regenerative thermal oxidizers, commonly referred to as RTOs, are essential in the effective and economical removal of hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) from industrial emissions. These thermal oxidizers are specialized combustion systems incorporated into the ventilation of industrial operations that produce potentially harmful pollutants. Read More

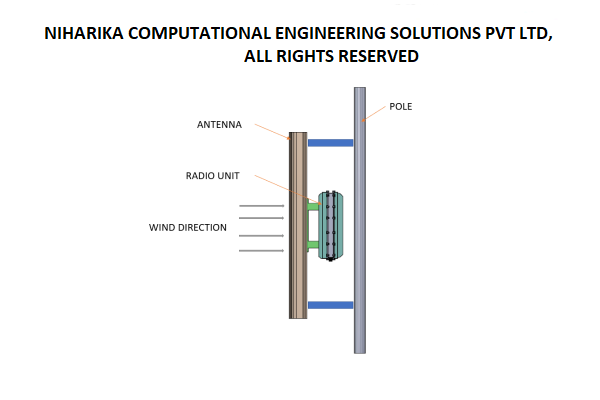

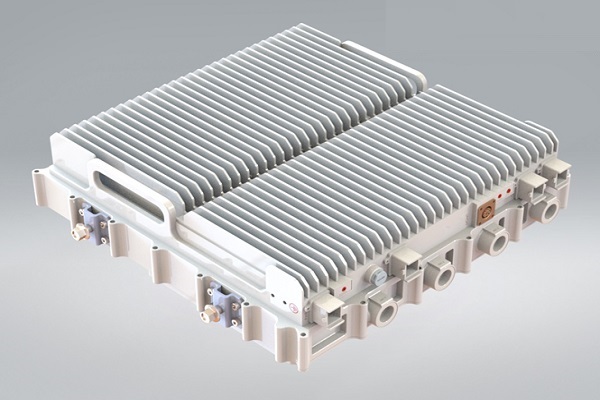

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units. Read More