GaN RF POWER AMPLIFIER : AN OVERVIEW

The demand for high-power and efficient radio frequency (RF) power amplifiers has been steadily increasing across various industries, including wireless communications, radar systems, and satellite communication. GaN (Gallium Nitride) technology has emerged as a game-changer in RF power amplification due to its exceptional performance characteristics and advantages over traditional technologies. GaN technology offers higher power density, improved efficiency, and wide bandwidth capability, setting it apart from traditional technologies like GaAs (Gallium Arsenide) or SiC (Silicon Carbide). With impressive power gain capabilities, excellent linearity, and low noise figures, GaN RF power amplifiers are well-suited for applications such as radar systems, satellite communications, and cellular base stations. However, the efficient operation of GaN RF modules heavily relies on effective thermal management. The excessive heat generated during operation can negatively impact reliability, degrade performance, and even cause premature failure. Therefore, implementing an appropriate thermal solution is crucial to ensure optimal and reliable functioning of GaN RF modules.

GaN RF POWER AMPLIFIER FOR ELECTRONIC WARFARE APPLICATIONS

Electronic warfare systems comprise a range of elements, such as radar systems, communication systems, jammers, and receivers. These components collaborate to identify, analyze, and counteract electromagnetic signals originating from both friendly and hostile sources. GaN RF Power Amplifiers are instrumental in electronic warfare applications as they enhance the power and effectiveness of electronic countermeasures. They aid in jamming enemy communications and disrupting radar signals.

PROJECT OVERVIEW

Bharat Electronics Limited (BEL), our esteemed client, is a renowned global aerospace and defense electronics company operating under the Ministry of Defense, Government of India. BEL specializes in manufacturing cutting-edge electronic products and systems for the Army, Navy, and Air Force. In order to develop one of their electronic warfare equipment, BEL has entrusted Niharika Computational Engineering Solutions Pvt Ltd (NCES) with the crucial task of creating a comprehensive thermal cooling solution. Additionally, NCES will demonstrate the effectiveness of this cooling solution through Computational Fluid Dynamics (CFD) analysis . We are truly privileged to have been selected for this significant project and remain fully dedicated to delivering exceptional outcomes.

PROPOSED COOLING SOLUTION

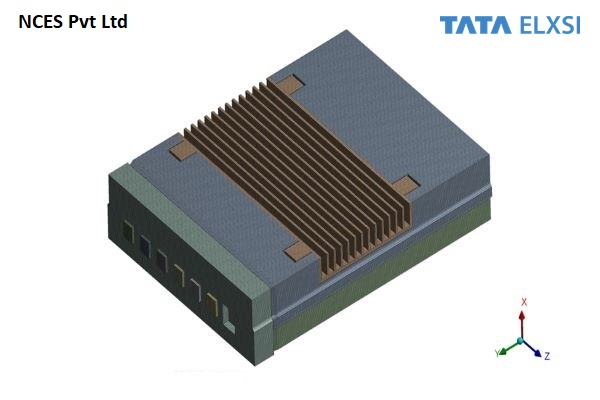

In the initial stages of the project, we considered utilizing a flat MHP (Micro Heat Pipe) with Dow Corning 340 Silicon heatsink compound as the thermal interface material. However, due to challenges in procuring a custom size MHP, we decided that a copper heat sink with a highly efficient thermal interface material would be a better alternative. Consequently, we conducted multiple design iterations, exploring various combinations of thermal interface materials. Ultimately, the final cooling system comprises a specially designed copper heat sink, a compact axial cooling fan, and a combination of graphite polymer and indium foil as thermal interface materials.

THERMAL INTERFACE MATERIALS

Selection of a suitable thermal interface material is crucial for the effective cooling of RF power amplifier, especially considering the heat flux of 200 Watt / Square Centimeter. Graphite polymer thermal interface materials are known for their exceptional inplane thermal conductivities, while Indium foil is renowned for its high cross plane thermal conductivity. Combination of graphite polymer thermal interface material with inplane thermal conductivities of up to 3000 W/mk and an Indium foil with a homogeneous thermal conductivity of 80 W/mk, has resulted in an outstanding cooling performance. This combination facilitated excellent heat transfer in the RF power amplifier, ensuring that the junction temperature is maintained with a comfortable 25 Degree Celsius margin.

CFD ANALYSIS DETAILS

Simplified CAD model of the RF Power amplifier unit is meshed with Hexahedral elements with a proper boundary layer resolution. The mesh size is 10 million. The flow is modeled as 3D, steady state, incompressible, viscous, and turbulent. Turbulence closure is modeled with the K-Omega SST Turbulence model, which accurately captures the boundary layer across the heat sink fins. Radiation inside the Amplifier assembly is modeled with a surface-to-surface (S2S) radiation enclosure model.

CFD analysis results have shown that there exists a 25 Degree Celsius margin for the Junction temperature of RF Power Amplifier. This result is obtained with a conservative approach.

Prototype test results have shown that there exists a 32 Degree Celsius margin for the Junction temperature of RF Power Amplifier and the proposed cooling solution is meeting all the functional requirements.

We Got More

Go through All Our Case Studies

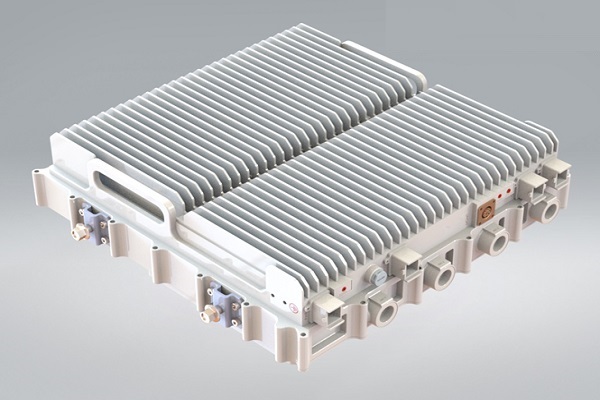

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units. Read More

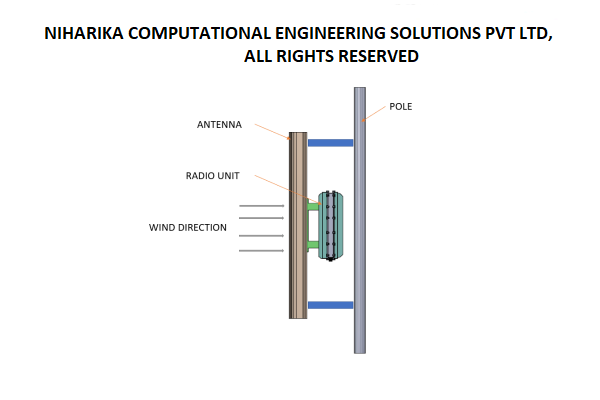

Wind Load analysis for multiband 5G Remote Radio Unit with Antenna using CFD

The seamless operation of base station antennas is of utmost importance for efficient and reliable communication networks. However, these antennas are constantly exposed to various environmental factors that can affect their performance and structural stability. Among these factors, wind load plays a significant role. Read More

AERODYNAMICS ANALYSIS OF TELECOM TOWER STRUCTURE

By meticulously considering the principles of aerodynamics in the design of telecom towers, engineers can effectively reduce wind induced vibrations. This not only enhances the overall experience for everyone but also guarantees the towers long term structural integrity and stability. Read More

Structural analysis for Triband Radio unit with antenna

In this project, we performed FEM analysis to check strength of the triband antenna model for the given load conditions. FE mesh consists of higher-order Tet elements & Hexahedral elements. Mesh size is 2810173 nodes & 1611495 elements. Appropriate contacts are modeled between all the parts in the assembly. FEM analysis is carried out as per the load conditions provided by the customer. We carried out Modal Analysis, Sine sweep Analysis (Harmonic Analysis), Random Vibration Analysis, Shock Analysis, Seismic Analysis, and Wind load Analysis. Read More

Structural analysis for 5G Remote Radio Unit

The advent of 5G technology has revolutionized the telecommunications industry, ushering in a new era of ultra-fast data speeds, low latency, and advanced network capabilities. Amidst this transformative landscape, the 5G Remote Radio Unit (RRU) emerges as a critical component, playing an instrumental role in the deployment and optimization of 5G networks. With 5G networks, RRUs have evolved to handle higher data volumes and faster speeds. They are designed to support an increasing number of devices and provide seamless connectivity even in densely populated areas. These modern marvels are a testament to the incredible progress made in wireless technology. Read More