Ensure Safety and Efficiency With CFD and FEA Services for Aerospace

Our Engineering services for the Aerospace and Defence Industry are mainly for Thermo vacuum systems, ground facilities, and mission-critical electronic systems.

Most of the projects we worked on are a part of the Government of India Initiatives towards self Reliance and Indigenisation.

We collaborated with Major Defence contractors in India and enabled them to design engineering systems that qualify for the stringent technical and safety norms specified by defense standard codes.

Our expertise in Computational Fluid Dynamics (CFD) analysis and Finite Element Analysis (FEA) have delivered immense value addition to complex defense ground facilities and mission-critical defense electronics.

Precise Engineering Solutions for Indian Aerospace and Defence Sector

We worked with reputed customers like the Indian Space Research Organization, the Defence Research and Development Organization, the Department of Atomic Energy, and Godrej Aerospace.

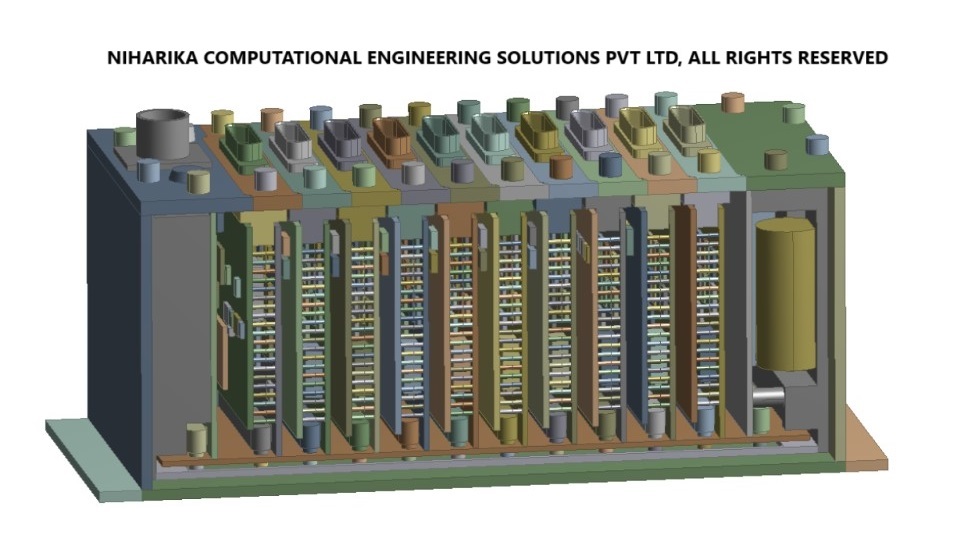

We assisted them in realizing operational excellence for high-temperature ground engineering systems like Chemical vacuum Infiltration (CVI) and Chemical vacuum deposition (CVD) furnaces, Rotary vacuum brazing furnaces (RVBF), and Tungsten furnaces.

We significantly contributed to the mission-critical defense and aerospace electronic systems like Telemetry power amplifiers, Telemetry processors, Telemetry transmitter, Flight data recorders, cockpit voice recorders, Flight Test Telemetry Units, Full Authority Digital Engine Control Unit (FADEC), and electronic power box units.

Our domain expertise, leveraged with computer-aided engineering simulation tools, has enabled us to arrive at precise analysis results, which allowed our customer to make conscious design decisions in the early stages of the product development cycle.

CFD and Thermal analysis

CFD analysis for high-temperature thermo- vacuum systems with operating temperatures in the range of 1500 to 4000 Degree Celsius

Transient CFD analysis to predict controlled heating and cooling rate in high-temperature thermal systems

Conduction, convection, and radiation modeling

Combustion modeling

Multi-phase Modeling

Structural analysis

Static / Dynamic analysis

Linear / Non-linear analysis

Modal analysis

Optimization

Analyzing and validating structural integrity and performance

Material characterization and Modeling

Mechanical design

Reverse Engineering

Concept Design

Sheet Metal Design

Chamber design

CAD Migration

Creo Services

UG-NX Services

2D to 3D Conversion

2D to 3D Modeling

Vector to Raster

Key Projects

CFD analysis of Rotary Vacuum Brazing Furnace-RVBF

Read More

Thermal and structural analysis of Chemical Vapor Infiltration and Chemical Vapor Deposition furnace

Read MoreCFD analysis of Digital aircraft engine controller-FADEC

Read More