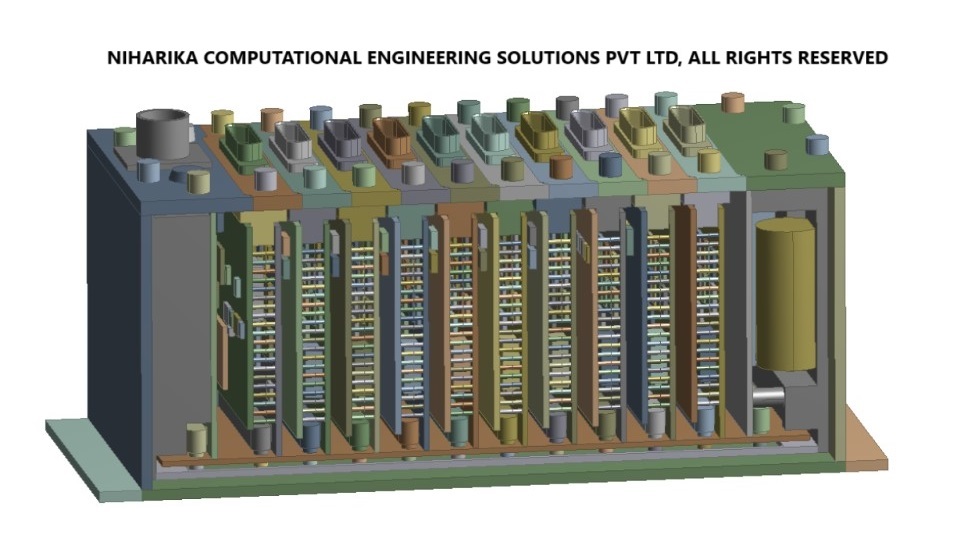

CFD analysis of Hybrid Cooled Data Center

Advanced AI and machine learning workloads are causing powerful GPUs to produce unprecedented heat levels in conventional server settings. Hybrid cooling solutions enable data center operators to manage these elevated temperatures without the need for complete retrofitting of current facilities, facilitating a gradual and cost-efficient method for incorporating liquid cooling tailored to specific high-heat applications.

Read More

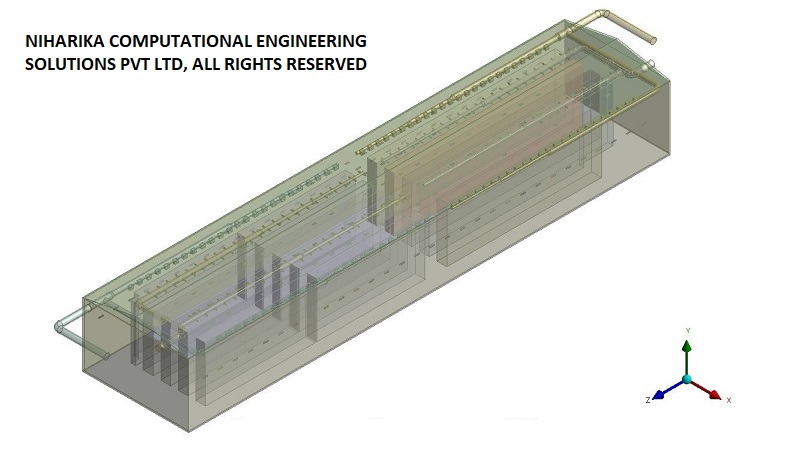

CFD analysis of Modular Data Center

Prefabricated modular data centers, often referred to as integrated modular solutions or containerized data centers, are designed to cater to specific business needs, providing a tailored and secure infrastructure that differs from conventional brick-and-mortar designs.

Read More

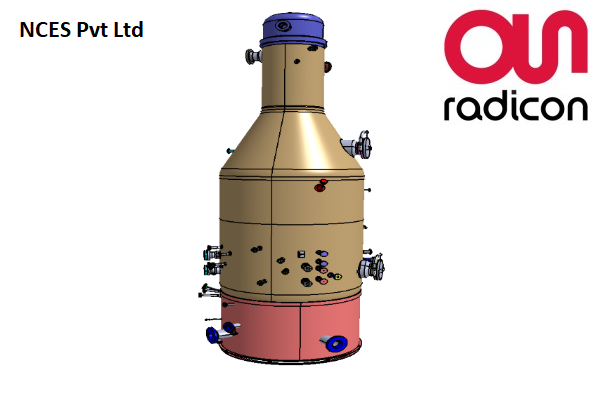

CFD Analysis of Regenerative Thermal Oxidizer

Regenerative thermal oxidizers, commonly referred to as RTOs, are essential in the effective and economical removal of hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) from industrial emissions. These thermal oxidizers are specialized combustion systems incorporated into the ventilation of industrial operations that produce potentially harmful pollutants.

Read More

CFD analysis of Ventilation System in Shoe Manufacturing Factory-Taiwan Client

A construction engineering firm based in Taiwan has reached out to us for a CFD analysis to evaluate the effectiveness of the ventilation system in a shoe manufacturing facility currently under development. The project involves performing CFD analysis under various wind speed and ambient temperature scenarios in accordance with ISHRAE standards.

Read More

Turnkey solution to Wind Induced Noise in High Rise Building:Mahindra Windchimes Residential Tower01and02,Bangalore

Mahindra Windchimes is a high-rise residential complex situated on the outskirts of Bangalore, directly exposed to winds from the Bannerghatta reserved forest area. Residents have reported significant acoustic disturbances in the reception and common areas on the ground and first floors of Towers 01 and 02. To address this concern, Mahindra Life Space Developers Limited has engaged Niharika Computational Engineering Solutions Private Limited (NCES) for a comprehensive engineering project.

Read More

CFD analysis of anaerobic Bio digester-Multiphase flow CFD analysis

. Effective mixing within the digester promotes biological, chemical, and physical uniformity, preventing the creation of dead zones that hinder substrate conversion. Insufficient mixing can lead to reduced digester performance, while excessive mixing may disrupt the digestion process due to high shear forces. Therefore, it is essential to thoroughly understand and examine the optimal mixing techniques in anaerobic digesters.

Read More

CFD analysis of Vaccine cold Storage warehouse HVAC System

A vaccine storage facility being constructed by Agility Pharma Logistics in Saudi Arabia requires an in-depth investigation of airflow dynamics and cooling processes within the warehouse through CFD analysis. To address this need, the contractor responsible for the cooling system has engaged Niharika Computational Engineering Solutions Pvt Ltd to perform a thorough CFD analysis and evaluate the air distribution in the planned ducting system.

Read More

Diagnostic study to eliminate resonant vibrations in vertical Turbine Pumps at JSW-Almatti Pumping station

After the implementation of the solution engineered by the NCES team, all the pumps have been operating without any vibration issues for six months. This is similar to the condition ten years ago when Larsen and Toubro Limited handed over the pumping station to JSW Limited.

Read More

FEM analysis for Telemetry Flight Test Instrumentation

PCAMI-1000 is an Airborne ruggedized Instrumentation System that handles excitation, attenuation, signal conditioning, data, embedded video and audio acquisition, encoding, operating numerous buses such as MIL 1553 and Arinc, and onboard data recording and data transmission with chassis of varied slot capacities such as 3, 6, 9 and 13 slots.

Read More

CFD analysis of Digital aircraft engine controller-FADEC

FADEC is a computer-managed aircraft ignition and engine control system used in modern commercial and military aircraft to control all aspects of engine performance digitally. Our client is a Government of India-approved Aerospace and Defense R&D unit.

Read More

Thermal and structural analysis of Chemical Vapor Infiltration and Chemical Vapor Deposition furnace

CVI and CVD is a thermo-vacuum chamber operating up to 2500 Degree Celsius. CVI-CVD furnace is mainly to mold high-temperature sustainable composites used in supersonic missiles.

This Thermo-vacuum facility is commissioned at DRDL- Hyderabad, the Defence Research and Development Organization (DRDO) propulsion complex, Ministry of Defence, Government of India.

The electromagnetic Induction heater is used to generate higher operating temperatures of the order of 2500 Degree Celsius.

Niharika Computational Engineering Solutions Pvt Ltd (NCES) has collaborated with the client and conducted Computational Fluid Dynamics (CFD) analysis to assess the thermal performance of the furnace. We also conducted structural analysis (FEA) to predict the thermal expansion of the plunger unit.

Read More

CFD analysis of Rotary Vacuum Brazing Furnace-RVBF

RVBF is an Inert gas-circulated, closed-loop Integrated thermal system with operating temperatures up to 1500 Deg Celsius. The Integrated thermal loop consists of a heat treatment chamber, a centrifugal blower for gas circulation, Shell and Tube Heat exchanger to achieve gas cooling, and an Electromagnetic Induction heater to reach a higher operating temperature.

Controlled cooling of the job is essential to achieve the desired metallurgical structure after heat treatment.

Niharika Computational Engineering Solutions Pvt Ltd (NCES) has collaborated with the client and analyzed the overall thermal performance of RVBF.

We conducted transient Computational Fluid Dynamics (CFD) analysis to analyze the cooling of the job during the cooling cycle.

Our CFD analysis process is validated with the help of experimental data obtained from the existing RVBF unit, which is of slightly lower capacity.

Read More

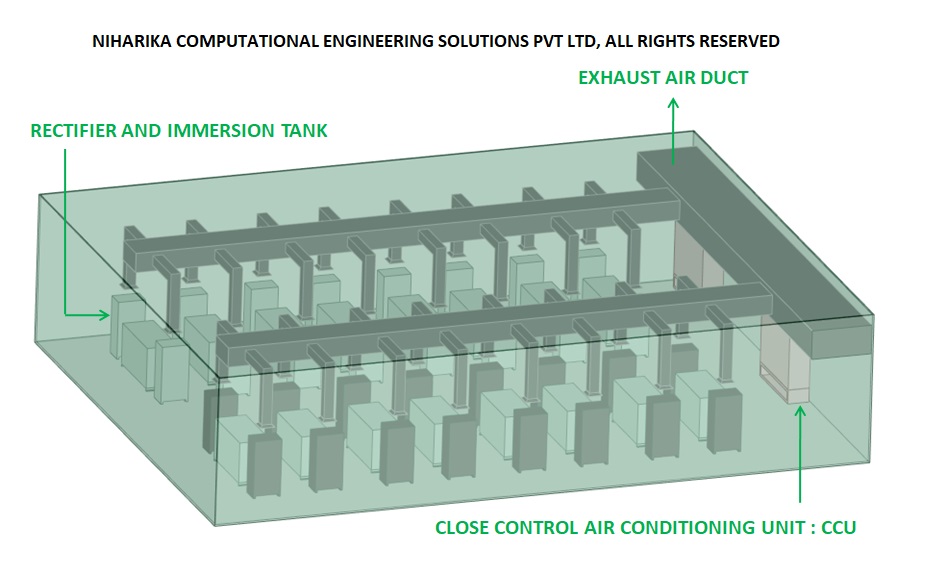

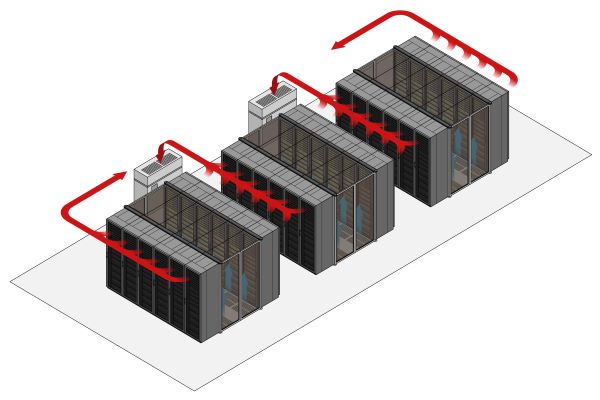

Optimization of hot and cold aisle rack/cabinet configuration in a data center using CFD analysis

The hot and cold aisles in the data center are part of an energy-efficient layout for server racks and other computing equipment. The goal of a hot/cold aisle configuration is to manage airflow in a way that conserves energy and lowers cooling costs. A containment system isolates hot and cold aisles from each other and prevents hot and cold air from mixing.

Our client is executing a turnkey contract for a bank data center in Kuwait. We worked with our client from the beginning stage of the project and assisted them with our Computational Fluid Dynamics (CFD) analysis results. Our CFD analysis results have enabled our client to arrive at the best operating sequence of the cooling units.

Read More

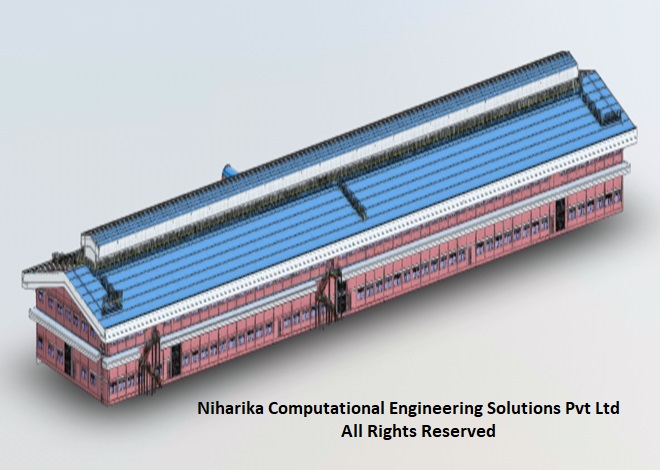

CFD analysis for General Electric data center,Bihar,India

Computational Fluid Dynamics (CFD) analysis is extensively used in data center projects to study the flow development and temperature field and identify the thermal hot spots in the projects design stage.

CFD analysis results enable the thermal designer to make well-informed decisions in the design stage and eliminate all the uncertainties that may affect the electronic equipment mounted in the racks.

We carried out CFD analysis for the large data center under construction in the Bihar state of India by Shapoorji and Pallonji EPC company, one of the largest EPC Companies in India.

Our CFD analysis results have enabled our customers to optimize the air-cooling system and ultimately to realize an efficient, safer, and effective data center cooling mechanism.

Read More

CFD analysis to predict flow development in wind turbine blade mold facility-LM Wind Power-India

We carried out CFD analysis for the HVAC Jet Nozzle system proposed in the Wind turbine blade molding division at the LM wind power blade manufacturing plant in Bangalore. The blade manufacturing plant consists of four molding bays; for each bay, cold air will be supplied through 2 AHU units. Each AHU unit is connected to 40 Jet Nozzles.

The main objective of CFD analysis is to analyze airflow, air-impinging angle, and the flow regime. The flow regime plays a significant role from Health and safety perspective.

We have explained our results to the Management of LM Wind power and recommended suggestions for Improvement.

Read More

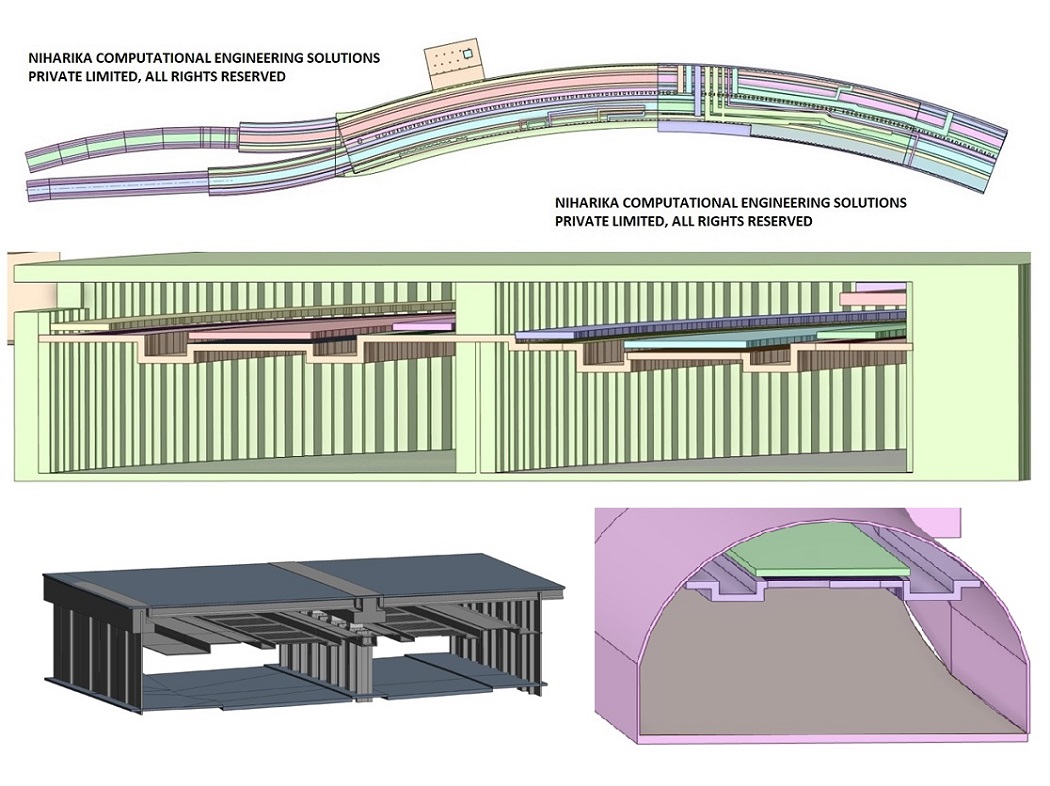

CFD analysis for underground transport tunnel:Al Shamiya Expansion Project,Makkah,Saudi Arabia

Underground tunnel infrastructure offers faster direct routes and excellent connectivity between communities.

The tunnel needs a reliable ventilation system for continuous air provision to limit the concentration of air pollutants during normal tunnel operation and to transport smoke gases out of the tunnel during emergency smoke extraction.

Our Computational Fluid Dynamics (CFD) simulation results have enabled our client to understand the flow development in the complete tunnel and gain confidence in the proposed Jet fans and various operating combinations of motorized dampers for smoke extraction in an emergency.

Our precise CFD analysis results have enabled our client to make conscious engineering decisions to achieve better resource efficiency and safety compliance.

Read More

CFD analysis of Wind turbine Generator unit

This project is executed for Siemens Gamesa Renewable Energy. The objective is to conduct CFD analysis for the Wind Turbine generator (WTG) unit at

the assembly level and to estimate the temperature developed on all the subsystems

We carried out CFD analysis for two configurations,

a) The existing configuration consists of four exhaust fans on top of the WTG system and converter refrigerant cooling fan capacity is 1.5 KW.

b) The proposed configuration with three exhaust fans at the top of the WTG system and converter refrigerant cooling fan capacity is enhanced to 2.6 KW

All the major subsystems in the WTG unit, like transformers, Generator &

slip ring system, converter panel, gearbox unit, hydraulic oil tank and

converter coolant (refrigerant) systems are considered in the CFD analysis.

Read More

Structural analysis of crude oil storage tank

The scope of the work is to validate the structural design of a 32 Kilo Litre crude oil storage tank employed in the Adani Petrochemical plant.

Our customer has approached us to validate the tank and cone roof design using Finite Element Analysis (FEA). We conducted FEM analysis, worked collaboratively with our customer, and enabled them to address all the minor uncertainties.

In the end, we concluded that the design met all the structural requirements.

Read More

Cement grinding plant Roller shaft re-design and FEM analysis

Frequent failure of the shaft used in cement grinding units at our customers plants across India warranted an independent review of the shaft design. Niharika Computational Engineering Solutions Pvt. Ltd. (NCES) was chosen for this Independent review task using the finite element method.

NCES was provided with information on the working principles of the roll press system and also information on the material used for the shaft that is in question, along with detailed drawings.

To better understand the design of the shaft for various loads that it would see during normal operation, a comprehensive study was undertaken by the NCES team. This study involved using Finite Element Analysis (FEA) and performing static analysis for load distribution, modal analysis for estimating natural frequencies, rotor dynamics for checking resonance due to vibration, and dynamic analysis to estimate endurance limit under complex loading and crack initiation and propagation.

NCES team has modified the shaft design and recommended a new material that addresses the frequent failure of the shaft.

Read More

CFD analysis of Helical Agitator

Helical agitators are a type of mixing equipment consisting of ribs or blades arranged in the form of a helix. This design creates axial motion and vigorous fluid motion inside a vessel. It is often used to mix viscous materials. The helical agitator is commonly used for low Reynolds number industrial mixing. The helical design of these agitators generates high shear rates and ensures thorough mixing of materials with different densities and viscosities. Helical agitators are used in polymer industries and other industries that require the use of quite viscous materials.

Read More

Pollution dispersion studies for SABIC chemical plant stack using Computational Fluid Dynamics (CFD)

We executed this project for a SABIC chemical plant in Al Jubail, Saudi Arabia. The objective of the project is to dilute the concentration of pollutants in the high-rise stack by injecting steam generated from the waste heater boiler.

We carried out CFD analysis and analyzed the reduction in the concentration of pollutants.

We designed a sparger which enabled us to increase the effective height of the stack.

Read More

Mechanical and Structural design of Disk baffle for Oligomerisation reactor

We executed this project for a SABIC Petrochemical plant located in Al Jubail, Saudi Arabia. The proposed disk baffle is expected to serve the function of separating the condensate in the Oligomerisation reactor.

We developed the conceptual model of the disk baffle using our expertise in core mechanical design and optimized the design using Finite Element Analysis (FEA). We provided detailed fabrication drawings to the customer and supported them during Fabrication process.

Read More

CFD analysis of dry powder inhaler and spacer

Optimal lung deposition of medication depends on the inbuilt resistance of the inhaler and the respiratory flow generated by the patient. Our client is a multinational conglomerate company based in London. Our collaboration has enabled them to analyze flow resistance in the dry powder inhaler for a range of inspiratory flow generated by patients from mild to severe chronic obstructive pulmonary disease.

We employed precise CFD analysis practices to accurately capture the boundary layer and adopted meticulous verification steps to justify CFD analysis results. We delivered technically convincing CFD analysis results close to experimental values.

Read More

Computational fluid dynamics analysis of neonatal body temperature controller unit

The Neonatal body temperature controller, an initiative by the Government of India, aims to protect newborn babies from Hypoxic ischemic encephalopathy. Our client is working with the Government of India and the Government of Karnataka state to develop this technology for usage in Primary Health care Centers in rural and remote areas.

Read More

Thermal analysis of high voltage X-ray tank assembly

The client is a global medical device OEM, one of the fastest growing in this segment. The client has approached us with the existing design of the high-voltage X ray tank unit. The client is interested in understanding the heat transfer phenomena for the complete system, which enables him to make conscious engineering decisions to enhance the performance of the device.

Our CFD model is validated with the experimental results. CFD model is finetuned in all possible aspects, and we ensured that it represents the actual physical phenomena.

All the heat transfer paths are analyzed, and the heat balance sheet has enabled our client to take well-informed engineering designs.

Read More

CFD analysis of closed-loop anesthesia delivery system (CLADS)

Closed loop anesthesia delivery systems are specifically engineered to automate and enhance the administration of anesthesia throughout surgical procedures. By constantly monitoring crucial indicators like oxygen levels and breathing patterns, these systems intelligently adapt the anesthesia dosage to ensure the patient receives the precise amount required at any given moment. This not only enhances the overall efficiency of the procedure but also significantly improves its safety.

Read More

CFD analysis of Electronics control box

We executed this project for an electronics manufacturer in ISRAEL.

The client has approached us with the initial thermal design. We performed a Computational Fluid Dynamics simulation (CFD analysis) and identified the thermal hot spots.

We modified the heat sink design with our strong domain expertise, provided heat diffusers at critical locations, and finetuned the design from a thermal perspective.

We performed thermal analysis for a worst-case scenario, and our engineering practices have enhanced our clients confidence.

Read More

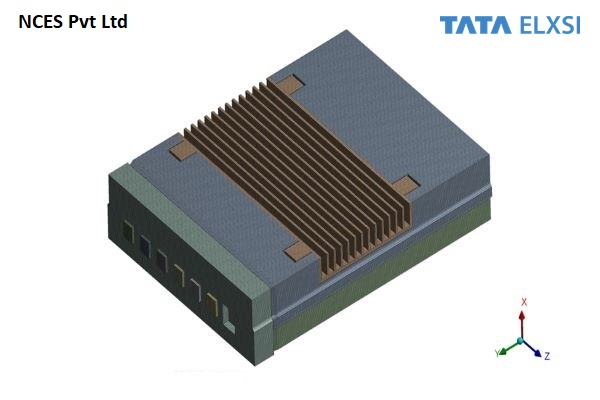

CFD analysis and thermal optimization for automotive Power train controller unit

Our Client TATA Elxsi has approached us to optimize the thermal design of the Automotive Power train controller unit. The client has come with dimensional constraints and inputs from the Electronics hardware team. We have guided the client starting from conceptual heat sink design, performed Computational Fluid Dynamics (CFD) analysis, fine-tuned the design with the help of CFD analysis results, and finally presented our part of the work to the Japanese end user. We have addressed heat dissipation, thermal contact resistance, and other input data uncertainties.

Read More

Structural analysis for 5G Remote Radio Unit

The advent of 5G technology has revolutionized the telecommunications industry, ushering in a new era of ultra-fast data speeds, low latency, and advanced network capabilities. Amidst this transformative landscape, the 5G Remote Radio Unit (RRU) emerges as a critical component, playing an instrumental role in the deployment and optimization of 5G networks.

With 5G networks, RRUs have evolved to handle higher data volumes and faster speeds. They are designed to support an increasing number of devices and provide seamless connectivity even in densely populated areas. These modern marvels are a testament to the incredible progress made in wireless technology.

Read More

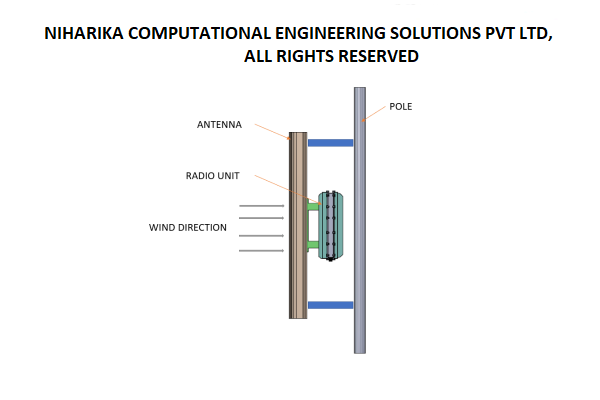

Structural analysis for Triband Radio unit with antenna

In this project, we performed FEM analysis to check strength of the triband antenna model for the given load conditions.

FE mesh consists of higher-order Tet elements & Hexahedral elements. Mesh size is 2810173 nodes & 1611495 elements. Appropriate contacts are modeled between all the parts in the assembly. FEM analysis is carried out as per the load conditions provided by the customer. We carried out Modal Analysis, Sine sweep Analysis (Harmonic Analysis), Random Vibration Analysis, Shock Analysis, Seismic Analysis, and Wind load Analysis.

Read More

AERODYNAMICS ANALYSIS OF TELECOM TOWER STRUCTURE

By meticulously considering the principles of aerodynamics in the design of telecom towers, engineers can effectively reduce wind induced vibrations. This not only enhances the overall experience for everyone but also guarantees the towers long term structural integrity and stability.

Read More

DEVELOPMENT OF COOLING SOLUTION FOR GaN RF POWER AMPLIFIER

The demand for high-power and efficient radio frequency (RF) power amplifiers has been steadily increasing across various industries, including wireless communications, radar systems, and satellite communication. GaN (Gallium Nitride) technology has emerged as a game-changer in RF power amplification due to its exceptional performance characteristics and advantages over traditional technologies.

GaN technology offers higher power density, improved efficiency, and wide bandwidth capability, setting it apart from traditional technologies like GaAs (Gallium Arsenide) or SiC (Silicon Carbide).

Read More

Wind Load analysis for multiband 5G Remote Radio Unit with Antenna using CFD

The seamless operation of base station antennas is of utmost importance for efficient and reliable communication networks. However, these antennas are constantly exposed to various environmental factors that can affect their performance and structural stability. Among these factors, wind load plays a significant role.

Read More

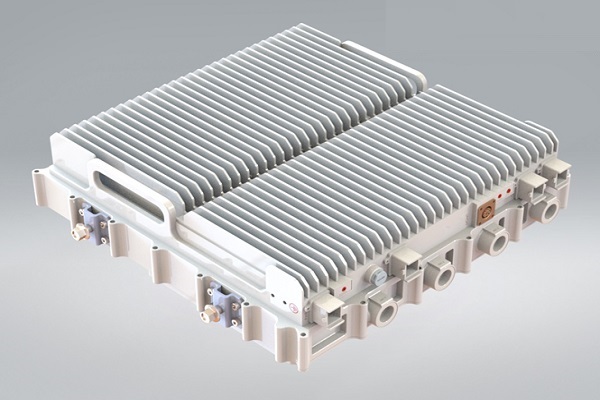

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units.

Read More