Scope of CFD analysis

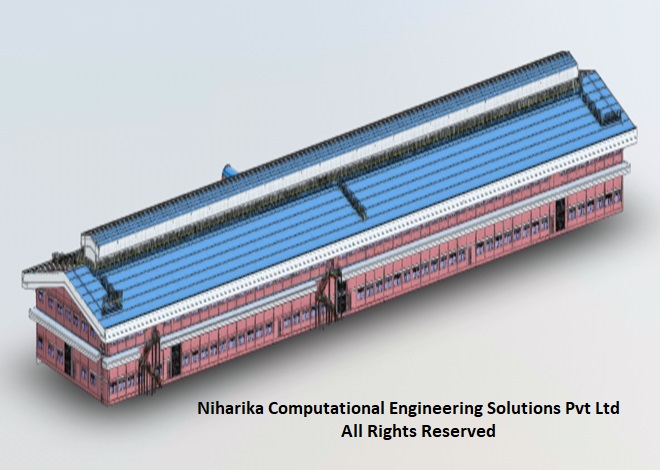

This shoe manufacturing facility spans an area of approximately 14,000 square meters. The anticipated thermal load generated by machinery, lighting, other equipment, and personnel within the factory is estimated to be around 900 kilowatts. The project involves analyzing the internal air circulation under both natural and forced convection conditions through Computational Fluid Dynamics (CFD) analysis. The ventilation system is comprised of propeller fans, exhaust fans, windows, and doors. The project scope includes the creation of a 3D CAD model based on the 2D drawings provided by the client, the generation of a CFD mesh, and the execution of CFD analysis for both natural and forced convection scenarios. The CFD analysis will identify flow dead zones, thermal hotspots, and areas requiring enhancement from a thermal comfort standpoint, and will illustrate the necessary modifications through a revised CFD analysis model.

CFD model development

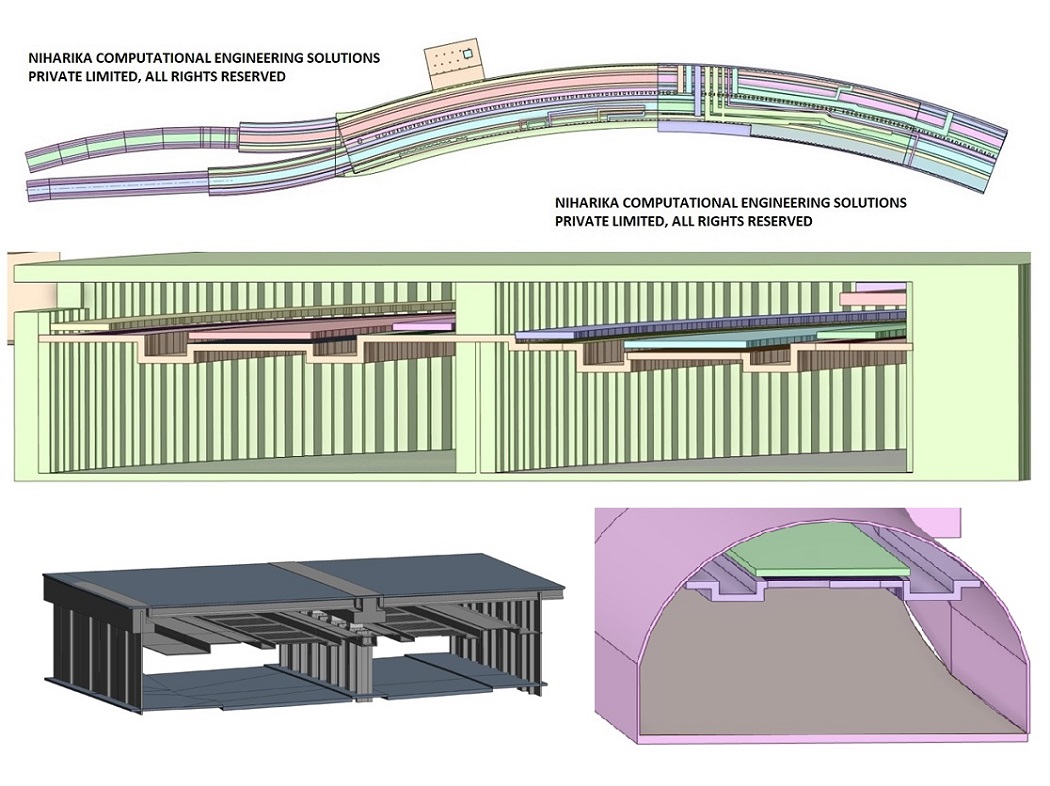

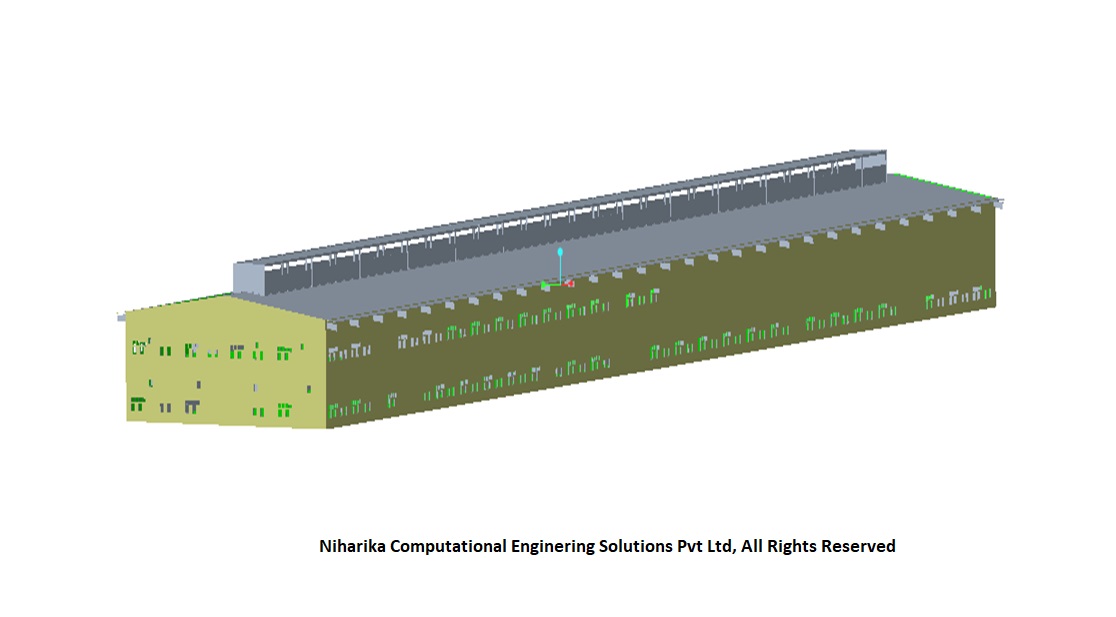

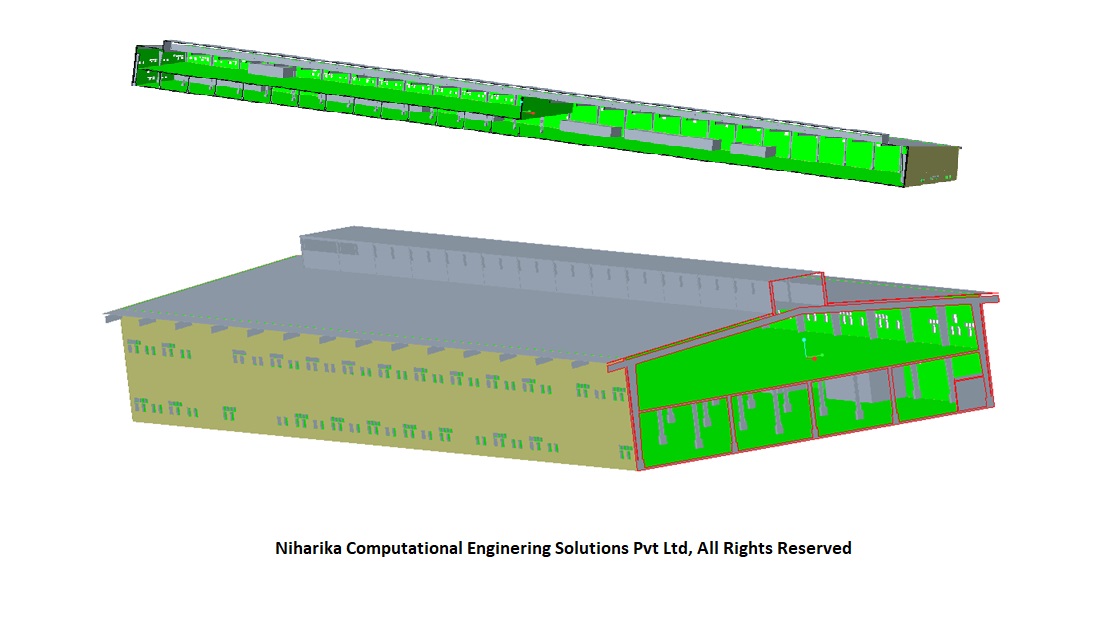

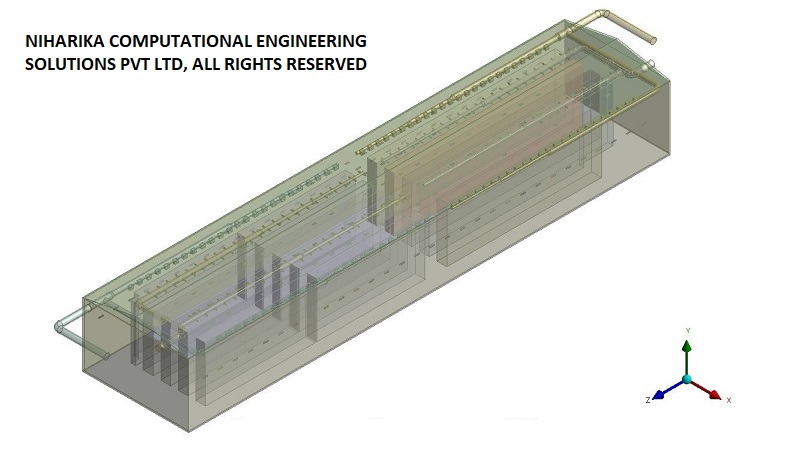

A 3D CAD model is created as needed using PTC Creo software, utilizing the AutoCAD drawings supplied by the Client. The Rivet Architectural model is referenced alongside the AutoCAD drawings during the development of the 3D CAD model. Computational Fluid Dynamics (CFD) meshing and analysis are conducted following the Client's approval of the 3D CAD model.

CAD Model Simplified for CFD analysis

3D CAD model is simplified keeping in view the physical phenomena and mesh quality, to achieve good convergence of the CFD solution. These activities are carried out in consultation with the client and obtaining necessary approval of the client.

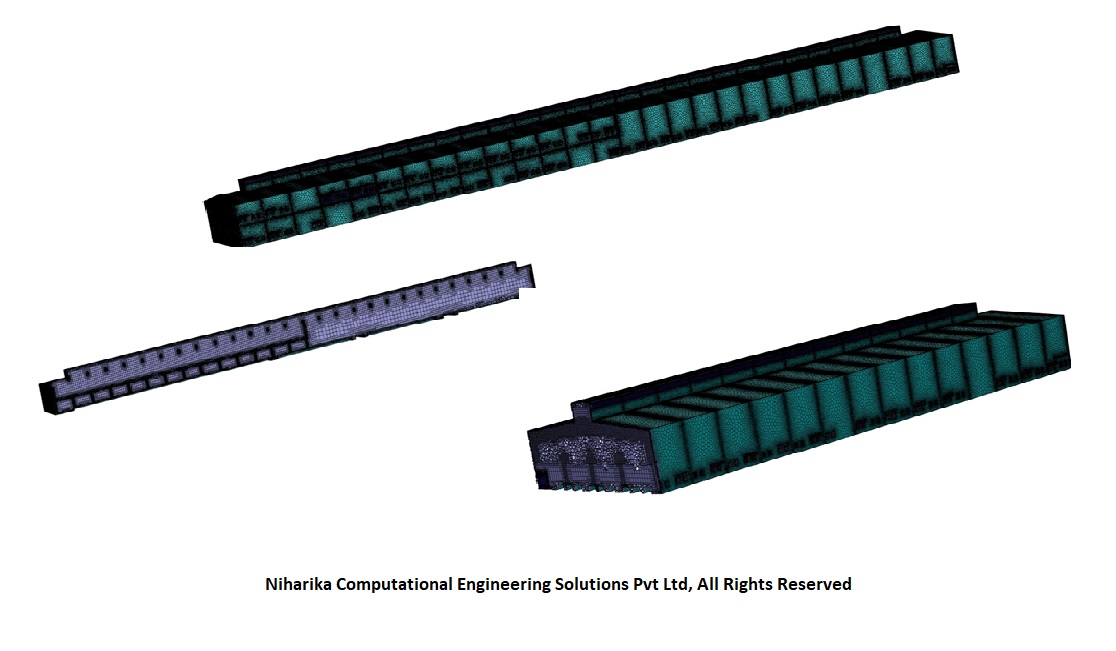

CFD mesh

CFD mesh has been created for the simplified 3D CAD model discussed in the previous section. This mesh is composed of Poly Hex core elements, with appropriate resolution in areas of high gradient, such as fans and ventilation ducts. The total cell count of the mesh is approximately 35 million, with optimal quality metrics that facilitated the attainment of a well-converged solution.

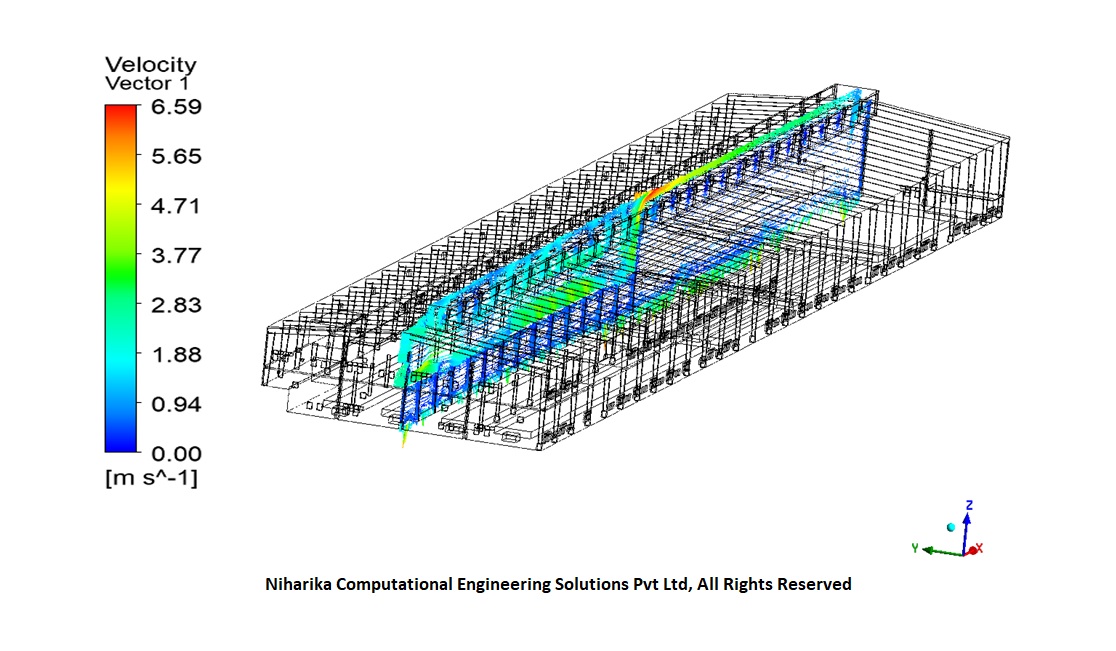

CFD analysis results - Velocity Field

A comprehensive examination of the velocity field derived from CFD analysis has allowed us to pinpoint the dead zones within the flow and implement suitable corrective actions. Additionally, the velocity field facilitated the optimization of fan placements and their directional orientation.

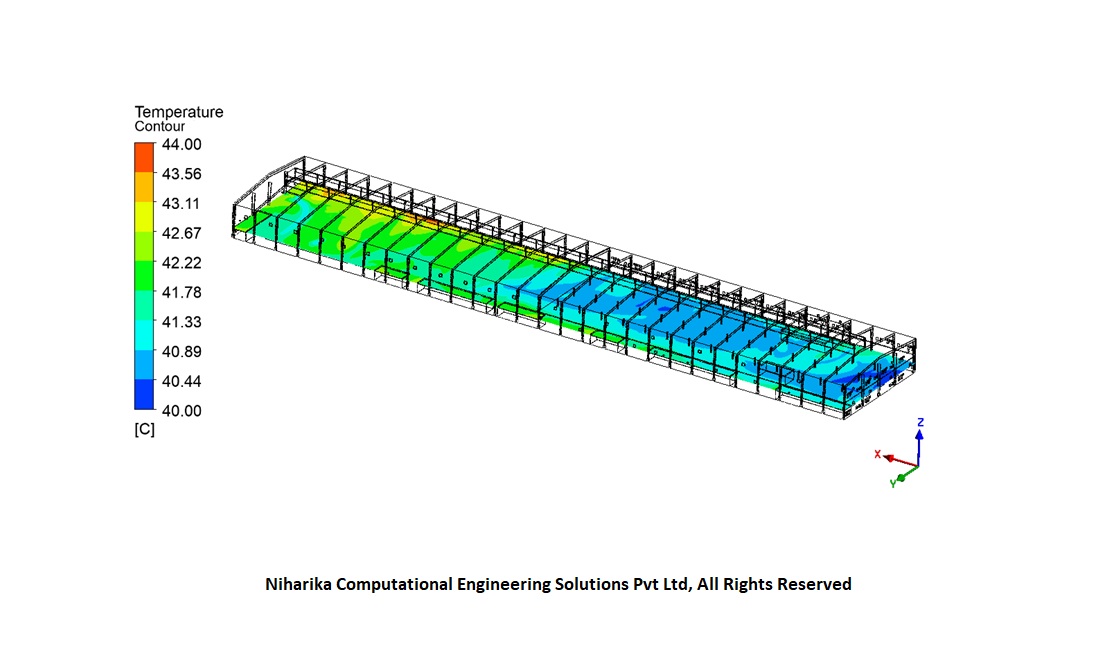

CFD analysis results - Temperature Field

A thorough analysis of the temperature distribution obtained from CFD studies has enabled us to identify the thermal hot spots in the factory area and take appropriate corrective measures.

Conclusions drawn from CFD analysis

Through CFD analysis, we have pinpointed the areas of stagnant flow and thermal hotspots. In collaboration with the Client, we have implemented corrective actions, and subsequent CFD analysis has been conducted to evaluate the improvements achieved from these measures.

We Got More

Go through All Our Case Studies

CFD analysis for underground transport tunnel:Al Shamiya Expansion Project,Makkah,Saudi Arabia

Underground tunnel infrastructure offers faster direct routes and excellent connectivity between communities. The tunnel needs a reliable ventilation system for continuous air provision to limit the concentration of air pollutants during normal tunnel operation and to transport smoke gases out of the tunnel during emergency smoke extraction. Our Computational Fluid Dynamics (CFD) simulation results have enabled our client to understand the flow development in the complete tunnel and gain confidence in the proposed Jet fans and various operating combinations of motorized dampers for smoke extraction in an emergency. Our precise CFD analysis results have enabled our client to make conscious engineering decisions to achieve better resource efficiency and safety compliance. Read MoreCFD analysis to predict flow development in wind turbine blade mold facility-LM Wind Power-India

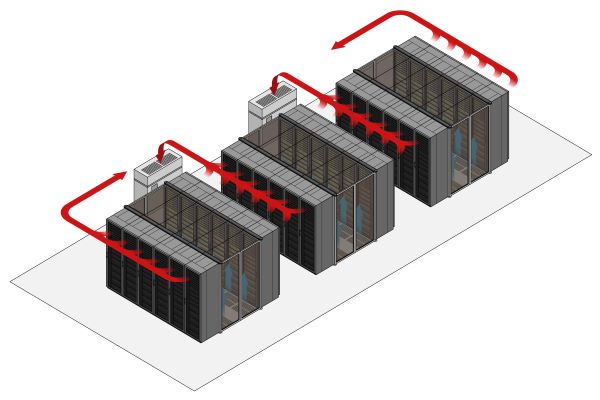

We carried out CFD analysis for the HVAC Jet Nozzle system proposed in the Wind turbine blade molding division at the LM wind power blade manufacturing plant in Bangalore. The blade manufacturing plant consists of four molding bays; for each bay, cold air will be supplied through 2 AHU units. Each AHU unit is connected to 40 Jet Nozzles. The main objective of CFD analysis is to analyze airflow, air-impinging angle, and the flow regime. The flow regime plays a significant role from Health and safety perspective. We have explained our results to the Management of LM Wind power and recommended suggestions for Improvement. Read MoreOptimization of hot and cold aisle rack/cabinet configuration in a data center using CFD analysis

The hot and cold aisles in the data center are part of an energy-efficient layout for server racks and other computing equipment. The goal of a hot/cold aisle configuration is to manage airflow in a way that conserves energy and lowers cooling costs. A containment system isolates hot and cold aisles from each other and prevents hot and cold air from mixing. Our client is executing a turnkey contract for a bank data center in Kuwait. We worked with our client from the beginning stage of the project and assisted them with our Computational Fluid Dynamics (CFD) analysis results. Our CFD analysis results have enabled our client to arrive at the best operating sequence of the cooling units. Read More

CFD analysis of Vaccine cold Storage warehouse HVAC System

A vaccine storage facility being constructed by Agility Pharma Logistics in Saudi Arabia requires an in-depth investigation of airflow dynamics and cooling processes within the warehouse through CFD analysis. To address this need, the contractor responsible for the cooling system has engaged Niharika Computational Engineering Solutions Pvt Ltd to perform a thorough CFD analysis and evaluate the air distribution in the planned ducting system. Read More

Turnkey solution to Wind Induced Noise in High Rise Building:Mahindra Windchimes Residential Tower01and02,Bangalore

Mahindra Windchimes is a high-rise residential complex situated on the outskirts of Bangalore, directly exposed to winds from the Bannerghatta reserved forest area. Residents have reported significant acoustic disturbances in the reception and common areas on the ground and first floors of Towers 01 and 02. To address this concern, Mahindra Life Space Developers Limited has engaged Niharika Computational Engineering Solutions Private Limited (NCES) for a comprehensive engineering project. Read More