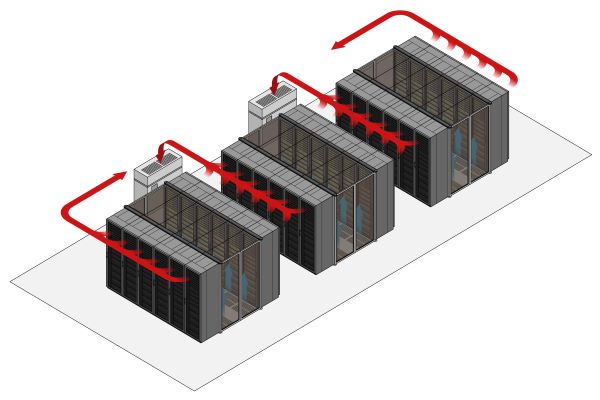

OVERVIEW OF HOT AND COLD AISLE CABINET DATA CENTRE:

In the current fast-paced technological environment, effectively managing data centers has become an essential element for organizations aiming to enhance performance and minimize operational expenses. A key aspect of achieving this goal involves adopting hot and cold aisle containment strategies within server racks. Hot and cold aisle racks are the configurations used in data centers to optimize airflow and temperature control. The hot aisle contains equipment that expels hot air, while the cold aisle draws in cool air to maintain ideal operating conditions for servers and other hardware. By segregating airflow and strategically managing temperature variations, hot and cold aisle configurations play a pivotal role in maintaining the ideal operating conditions for IT equipment and improves overall efficiency. Carefully positioning of servers and racks in hot aisle is the key to ensuring proper airflow management. When setting up cold aisle racks in a data center, airflow direction and enclosure design are crucial factors to consider. Additionally, positioning of close control air conditioner (CCU) should facilitate proper airflow management to maximize cooling efficiency. Computational Fluid Dynamics (CFD) analysis offers a wide range of advantages, including the enhancement of energy efficiency and optimization of cooling systems. It also aids in reducing downtime, improving equipment performance, and achieving significant cost savings.

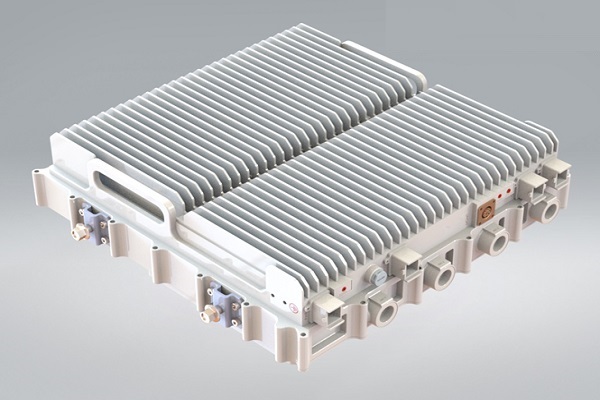

CLOSE CONTROL AIR CONDITIONER ( CCU)

CCU, also known as a close control air conditioner, a computer room air conditioner, or a server room air conditioner, is designed to regulate temperature and humidity to a precise fixed point. It comprises of an Indoor evaporator module and a condensing module. Additionally, the system includes a humidifier, a reheater, and a safety thermostat. The microprocessor is responsible for managing the entire unit and has the necessary capabilities to interact with other units to ensure environmental conditions are met.

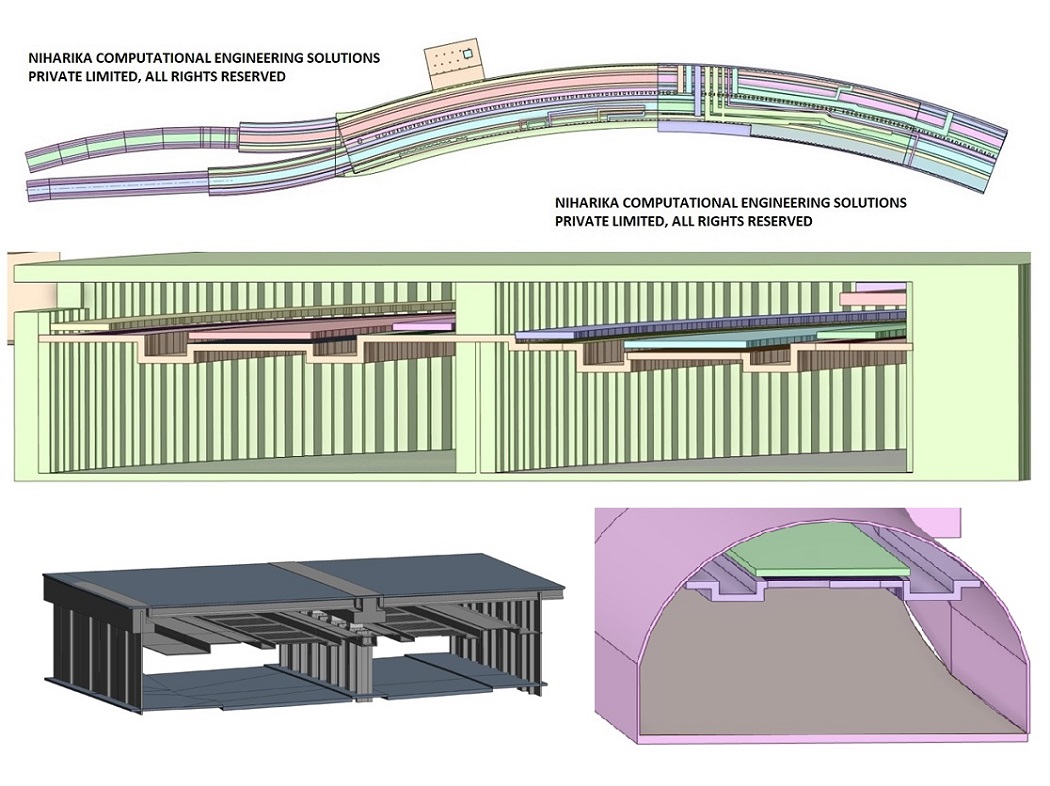

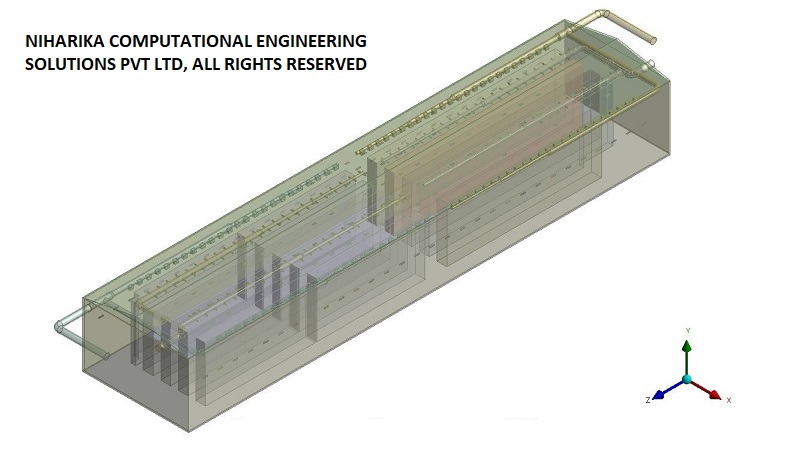

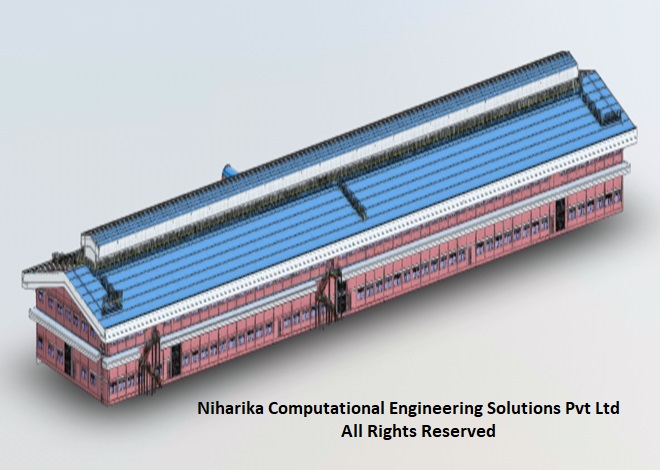

3D CAD MODEL DEVELOPMENT

The 3D CAD model of the data center is created using PTC Creo CAD software, utilizing the layout drawings provided by our client. The model is meticulously developed to meet the requirements for conducting CFD analysis.

CFD Mesh

Due to the large dimensions of the CAD model, it has been divided into four parts and a CFD mesh has been generated for each individual part. These meshed models are then assembled, ensuring that proper interfaces are provided according to the best practices in the CFD industry. The overall mesh count amounts to 24 million cells, comprising a combination of Polyhedral and Hexahedral elements (Poly Hex core mesh). The quality of the mesh has been maintained in accordance with the best practices in the CFD industry.

CFD Modelling

The flow is modelled as 3D, steady state, viscous and Incompressible. Turbulence closure is implemented using the K-Omega SST Turbulence model. Fan boundaries are applied at specific locations. Conjugate heat transfer effects are taken into consideration in the CFD analysis, while heat dissipation is simulated using a volumetric heat load approach.

HEAT LOAD

Total thermal load is about 950 KW, to be handled by 10 number of closed control air condition units (CCU). Out of the 10 CCU , 2 are always redundant.

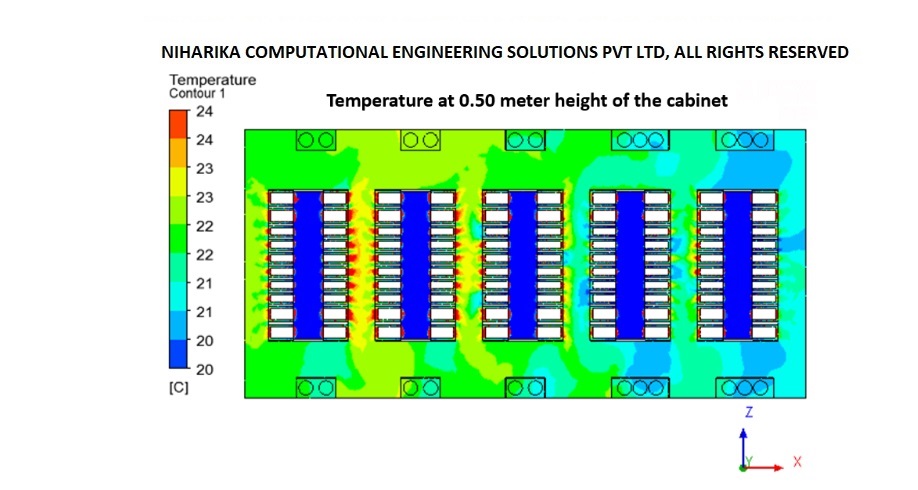

TEMPERATURE FIELD

The total thermal load is approximately 950 kW, which will be managed by ten closed control air conditioning units (CCUs). Among these ten units, two are designated as redundant. We conducted a CFD analysis for five distinct configurations, exploring all potential redundancy combinations of the CCU units. Based on the temperature field analysis, we provided recommendations to our client regarding which redundancy combinations should be avoided.

The results of the CFD analysis indicate that the cooling system implemented for this data centre is adequate, and there is a sufficient level of redundancy in place.

We Got More

Go through All Our Case Studies

CFD analysis for underground transport tunnel:Al Shamiya Expansion Project,Makkah,Saudi Arabia

Underground tunnel infrastructure offers faster direct routes and excellent connectivity between communities. The tunnel needs a reliable ventilation system for continuous air provision to limit the concentration of air pollutants during normal tunnel operation and to transport smoke gases out of the tunnel during emergency smoke extraction. Our Computational Fluid Dynamics (CFD) simulation results have enabled our client to understand the flow development in the complete tunnel and gain confidence in the proposed Jet fans and various operating combinations of motorized dampers for smoke extraction in an emergency. Our precise CFD analysis results have enabled our client to make conscious engineering decisions to achieve better resource efficiency and safety compliance. Read MoreCFD analysis to predict flow development in wind turbine blade mold facility-LM Wind Power-India

We carried out CFD analysis for the HVAC Jet Nozzle system proposed in the Wind turbine blade molding division at the LM wind power blade manufacturing plant in Bangalore. The blade manufacturing plant consists of four molding bays; for each bay, cold air will be supplied through 2 AHU units. Each AHU unit is connected to 40 Jet Nozzles. The main objective of CFD analysis is to analyze airflow, air-impinging angle, and the flow regime. The flow regime plays a significant role from Health and safety perspective. We have explained our results to the Management of LM Wind power and recommended suggestions for Improvement. Read More

CFD analysis of Vaccine cold Storage warehouse HVAC System

A vaccine storage facility being constructed by Agility Pharma Logistics in Saudi Arabia requires an in-depth investigation of airflow dynamics and cooling processes within the warehouse through CFD analysis. To address this need, the contractor responsible for the cooling system has engaged Niharika Computational Engineering Solutions Pvt Ltd to perform a thorough CFD analysis and evaluate the air distribution in the planned ducting system. Read More

Turnkey solution to Wind Induced Noise in High Rise Building:Mahindra Windchimes Residential Tower01and02,Bangalore

Mahindra Windchimes is a high-rise residential complex situated on the outskirts of Bangalore, directly exposed to winds from the Bannerghatta reserved forest area. Residents have reported significant acoustic disturbances in the reception and common areas on the ground and first floors of Towers 01 and 02. To address this concern, Mahindra Life Space Developers Limited has engaged Niharika Computational Engineering Solutions Private Limited (NCES) for a comprehensive engineering project. Read More

CFD analysis of Ventilation System in Shoe Manufacturing Factory-Taiwan Client

A construction engineering firm based in Taiwan has reached out to us for a CFD analysis to evaluate the effectiveness of the ventilation system in a shoe manufacturing facility currently under development. The project involves performing CFD analysis under various wind speed and ambient temperature scenarios in accordance with ISHRAE standards. Read More