OVER VIEW OF THE PROJECT

Hypoxic ischemic encephalopathy (HIE) is a critical and potentially fatal condition that arises in infants as a result of inadequate oxygen supply and diminished blood circulation to the brain. Failure to promptly identify and address this condition can result in substantial neurological harm and enduring disabilities. In recent times, hypothermia therapy has emerged as a hopeful intervention for HIE, presenting the possibility of safeguarding the nervous system and enhancing the prognosis for affected newborns. The Neonatal body temperature controller, an initiative by the Government of India, aims to protect newborn babies from Hypoxic ischemic encephalopathy. Our client is working with the Government of India and the Government of Karnataka state to develop this technology for usage in Primary Health care Centers in rural and remote areas. We have been entrusted with the task of conducting Computational Fluid Dynamics (CFD) analysis, interpreting the results, and optimizing the cooling network design to ensure adequate coolant flow throughout the proposed baby wrap. We are committed to fulfilling this responsibility and contributing to the success of this life-saving project. Our precise CFD simulation practices, deep knowledge in theoretical fluid dynamics have enabled us to optimize the coolant jacket to achieve the desired cooling performance.

HYPOTHERMIA THERAPY

Hypothermia therapy, also referred to as cooling therapy, involves the deliberate reduction of body temperature in infants with HIE. During this treatment, the infant's body temperature is carefully maintained between 33.5°C and 34.5°C for a continuous period of 72 hours. Following this, a gradual re-warming process takes place over a minimum of 4 hours, increasing the body temperature by 0.5°C per hour until it reaches the desired range of 36.5 to 37°C. The primary objective of this therapeutic approach is to decrease the metabolic demands on the brain and shield it from further harm. Cooling therapy has gained significant recognition as an effective intervention in managing HIE, as it holds the potential to enhance outcomes.

NEONATAL BODY TEMPERATURE CONTROLLER

A closed loop cooling blanket is utilized in the neonatal body temperature controller to regulate the baby's temperature. The blanket is filled with a thermally controlled water-glycol medium that circulates throughout. The baby is carefully wrapped in this cooling blanket, ensuring that both the head and the entire body are covered. Under close medical supervision, the baby's brain and entire body are cooled to a temperature slightly lower than the average body temperature for approximately 72 hours. Subsequently, the blanket is gradually warmed to return the baby to a moderate body temperature.

BENEFITS OF CFD ANALYSIS IN OPTIMIZING THE FLOW IN NEONATAL COOLING BLANKET

CFD analysis has emerged as a highly beneficial tool in the design of medical devices. The incorporation of Computational Fluid Dynamics (CFD) analysis into the development process of neo natal cooling blankets has provided us with valuable insights into their performance and functionality. Through the simulation of various scenarios, we have successfully identified areas that require improvement, such as enhancing the uniformity of coolant flow and reducing pressure drops, ultimately resulting in enhanced device functionality. Our utilization of advanced turbulence models and accurate boundary layer modelling options, combined with our High-Performance Computing Infrastructure, has enabled us to accurately predict the flow with the utmost precision. Leveraging the precise results obtained from CFD analysis, along with our profound understanding of fluid mechanics, we have been able to make well-informed decisions to optimize the cooling jacket for optimal performance.

CFD MESH GENERATION

The alpha prototype's 3D CAD model has been discretized using a Hybrid mesh, specifically with a fine resolution in the boundary layer region. The mesh count is approximately 11 million, ensuring the best quality Index. Through grid independence studies, the mesh has been optimized. As a result, the final mesh accurately resolves the flow and achieves stable and smooth convergence.

FLOW MODELLING

The 3D, steady state, incompressible, viscous, and turbulent flow is simulated. The turbulence closure is described by the K-Omega SST Turbulence model, with a y plus value of 0.8.

BOUNDARY CONDITIONS

The CFD model enforces a mass flow rate at the Inlet and a zero-gradient condition at the out. The walls are represented with a no slip condition.

CFD ANALYSIS RESULTS

By conducting CFD analysis, we have been able to observe and analyze the flow pattern, pressure distribution, turbulence, and vortex zones. Through simulating different mass flow rates and carefully analyzing the results, we were able to optimize the design and achieve optimal coolant distribution throughout the cooling jacket.

We Got More

Go through All Our Case Studies

CFD analysis of closed-loop anesthesia delivery system (CLADS)

Closed loop anesthesia delivery systems are specifically engineered to automate and enhance the administration of anesthesia throughout surgical procedures. By constantly monitoring crucial indicators like oxygen levels and breathing patterns, these systems intelligently adapt the anesthesia dosage to ensure the patient receives the precise amount required at any given moment. This not only enhances the overall efficiency of the procedure but also significantly improves its safety. Read More

Thermal analysis of high voltage X-ray tank assembly

The client is a global medical device OEM, one of the fastest growing in this segment. The client has approached us with the existing design of the high-voltage X ray tank unit. The client is interested in understanding the heat transfer phenomena for the complete system, which enables him to make conscious engineering decisions to enhance the performance of the device. Our CFD model is validated with the experimental results. CFD model is finetuned in all possible aspects, and we ensured that it represents the actual physical phenomena. All the heat transfer paths are analyzed, and the heat balance sheet has enabled our client to take well-informed engineering designs. Read More

CFD analysis of dry powder inhaler and spacer

Optimal lung deposition of medication depends on the inbuilt resistance of the inhaler and the respiratory flow generated by the patient. Our client is a multinational conglomerate company based in London. Our collaboration has enabled them to analyze flow resistance in the dry powder inhaler for a range of inspiratory flow generated by patients from mild to severe chronic obstructive pulmonary disease. We employed precise CFD analysis practices to accurately capture the boundary layer and adopted meticulous verification steps to justify CFD analysis results. We delivered technically convincing CFD analysis results close to experimental values. Read More

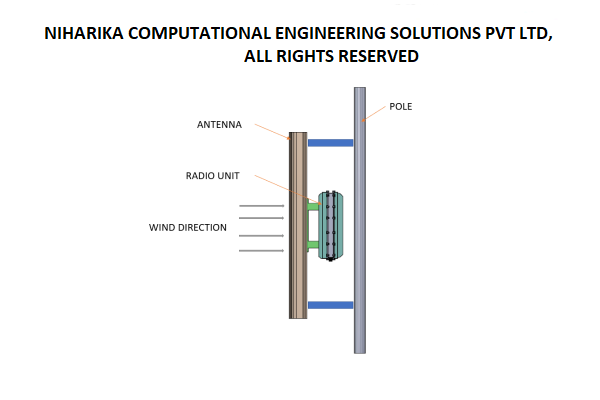

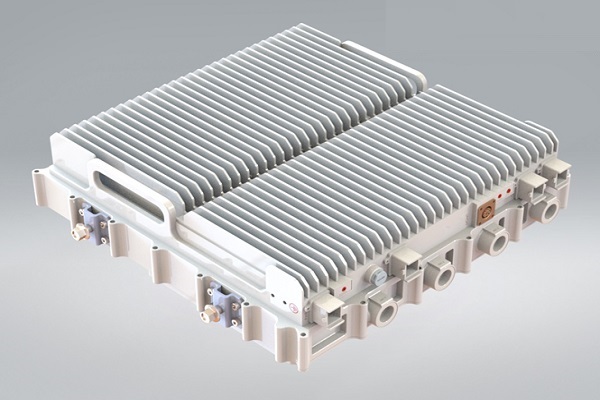

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units. Read More