PROJECT DETAILS

Frequent failure of the shaft used in cement grinding units at our customers plants across India warranted an independent review of the shaft design. Niharika Computational Engineering Solutions Pvt. Ltd. (NCES) was chosen for this Independent review task using the finite element method. NCES was provided with information on the working principles of the roll press system and also information on the material used for the shaft that is in question, along with detailed drawings. To better understand the design of the shaft for various loads that it would see during normal operation, a comprehensive study was undertaken by the NCES team. This study involved using Finite Element Analysis (FEA) and performing static analysis for load distribution, modal analysis for estimating natural frequencies, rotor dynamics for checking resonance due to vibration, and dynamic analysis to estimate endurance limit under complex loading and crack initiation and propagation. NCES team has modified the shaft design and recommended a new material that addresses the frequent failure of the shaft.

We Got More

Go through All Our Case Studies

Pollution dispersion studies for SABIC chemical plant stack using Computational Fluid Dynamics (CFD)

We executed this project for a SABIC chemical plant in Al Jubail, Saudi Arabia. The objective of the project is to dilute the concentration of pollutants in the high-rise stack by injecting steam generated from the waste heater boiler. We carried out CFD analysis and analyzed the reduction in the concentration of pollutants. We designed a sparger which enabled us to increase the effective height of the stack. Read More

Structural analysis of crude oil storage tank

The scope of the work is to validate the structural design of a 32 Kilo Litre crude oil storage tank employed in the Adani Petrochemical plant. Our customer has approached us to validate the tank and cone roof design using Finite Element Analysis (FEA). We conducted FEM analysis, worked collaboratively with our customer, and enabled them to address all the minor uncertainties. In the end, we concluded that the design met all the structural requirements. Read More

CFD analysis of Wind turbine Generator unit

This project is executed for Siemens Gamesa Renewable Energy. The objective is to conduct CFD analysis for the Wind Turbine generator (WTG) unit at the assembly level and to estimate the temperature developed on all the subsystems We carried out CFD analysis for two configurations, a) The existing configuration consists of four exhaust fans on top of the WTG system and converter refrigerant cooling fan capacity is 1.5 KW. b) The proposed configuration with three exhaust fans at the top of the WTG system and converter refrigerant cooling fan capacity is enhanced to 2.6 KW All the major subsystems in the WTG unit, like transformers, Generator & slip ring system, converter panel, gearbox unit, hydraulic oil tank and converter coolant (refrigerant) systems are considered in the CFD analysis. Read MoreDiagnostic study to eliminate resonant vibrations in vertical Turbine Pumps at JSW-Almatti Pumping station

After the implementation of the solution engineered by the NCES team, all the pumps have been operating without any vibration issues for six months. This is similar to the condition ten years ago when Larsen and Toubro Limited handed over the pumping station to JSW Limited. Read More

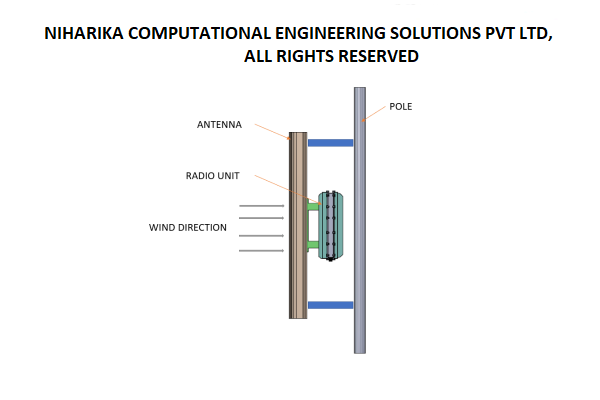

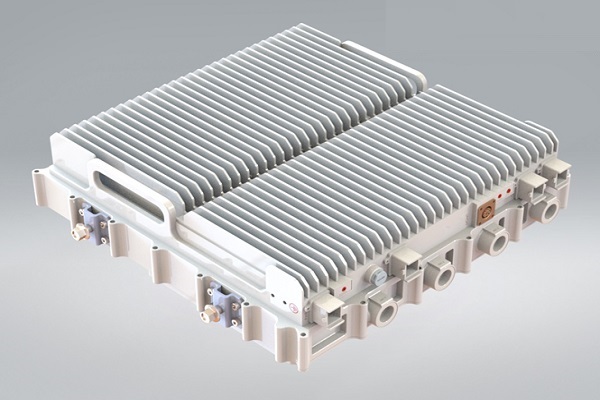

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units. Read More