PROJECT DETAILS

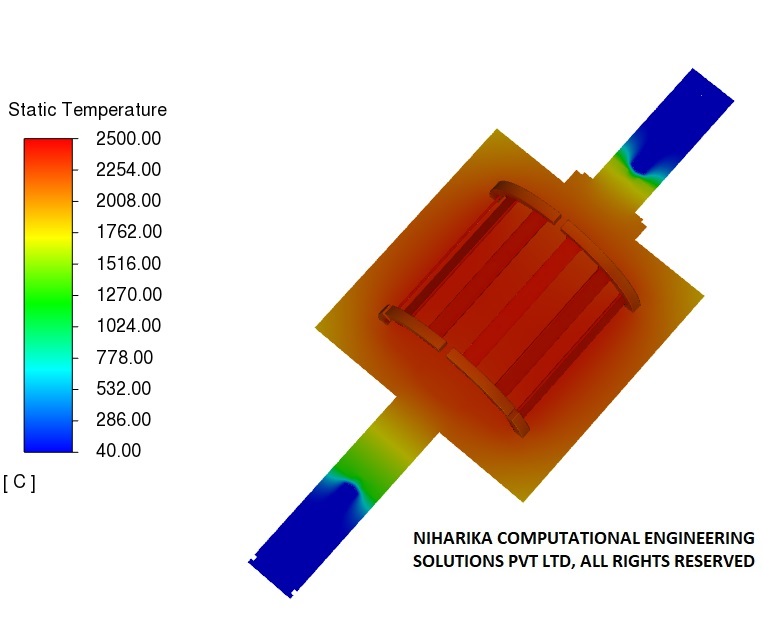

CVI and CVD is a thermo-vacuum chamber operating up to 2500 Degree Celsius. CVI-CVD furnace is mainly to mold high-temperature sustainable composites used in supersonic missiles. This Thermo-vacuum facility is commissioned at DRDL- Hyderabad, the Defence Research and Development Organization (DRDO) propulsion complex, Ministry of Defence, Government of India. The electromagnetic Induction heater is used to generate higher operating temperatures of the order of 2500 Degree Celsius. Niharika Computational Engineering Solutions Pvt Ltd (NCES) has collaborated with the client and conducted Computational Fluid Dynamics (CFD) analysis to assess the thermal performance of the furnace. We also conducted structural analysis (FEA) to predict the thermal expansion of the plunger unit.

The aim of this CFD analysis is to examine the temperature distribution, calculate the heat retention in individual components, and validate the design of the integrated cooling systems.

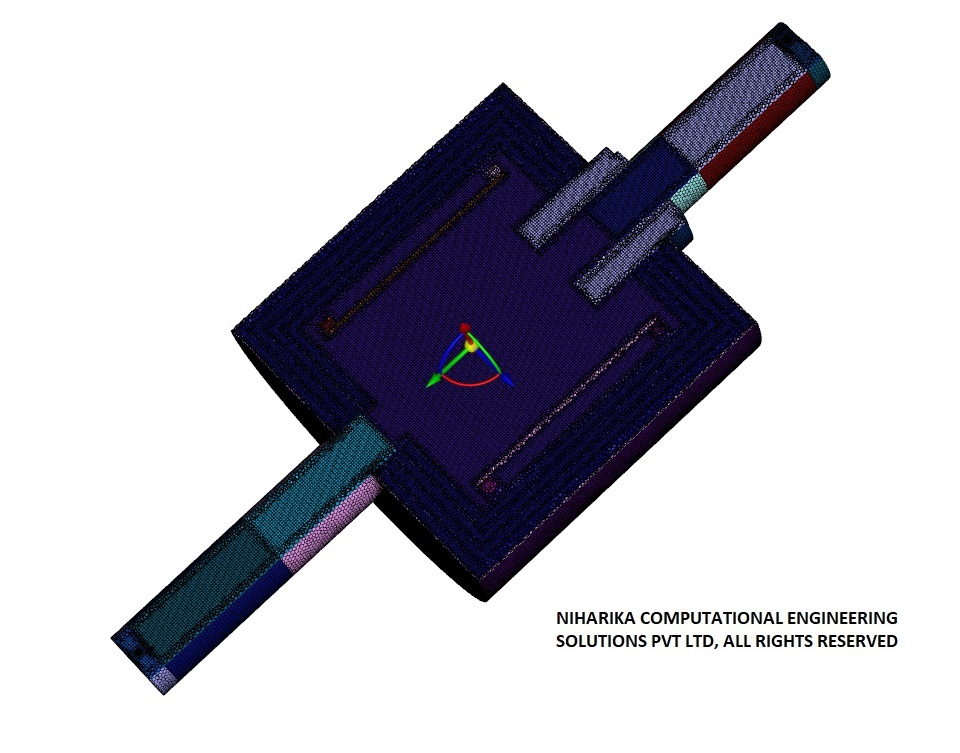

A poly hex core mesh has been developed for the streamlined CAD model, incorporating a high-resolution mesh in regions with significant gradients. This mesh consists of 12 million cells and exhibits quality metrics that conform to the established standards of CFD analysis.

Both steady-state and transient CFD analyses have been conducted for this thermo vacuum system. The material properties are tailored, utilizing the data supplied in the relevant material specification sheet from the manufacturer.

The results of the CFD analysis have demonstrated that the design of the induction heater satisfies the thermal requirements. The performance of the integrated cooling systems is deemed satisfactory.

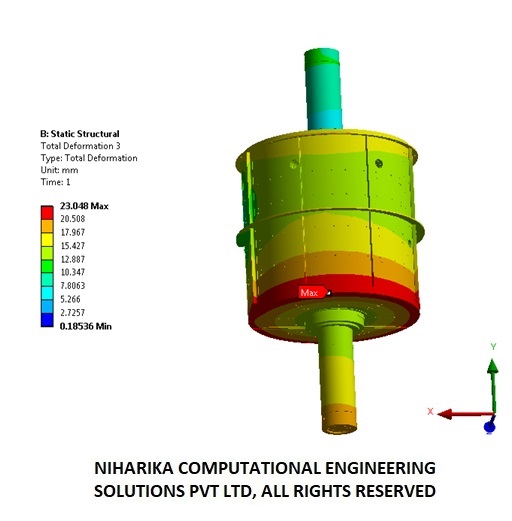

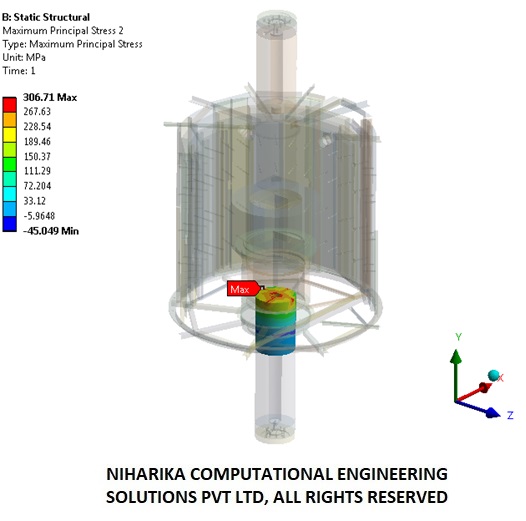

Finite Element Method (FEM) analysis is performed, utilizing the temperature data obtained from Computational Fluid Dynamics (CFD) analysis. The material properties are referenced according to the specifications provided by the manufacturers.

FEM analysis results have suggested that the stress values observed on the Steel parts are very near to Yield strength. The Tensile stress (Max. principal stress) observed on the Graphite are above Tensile strength of the Graphite. If we consider Compressive stress (Min. Principal stress), the stress values are below Compressive strength of Graphite.

We Got More

Go through All Our Case Studies

CFD analysis of Rotary Vacuum Brazing Furnace-RVBF

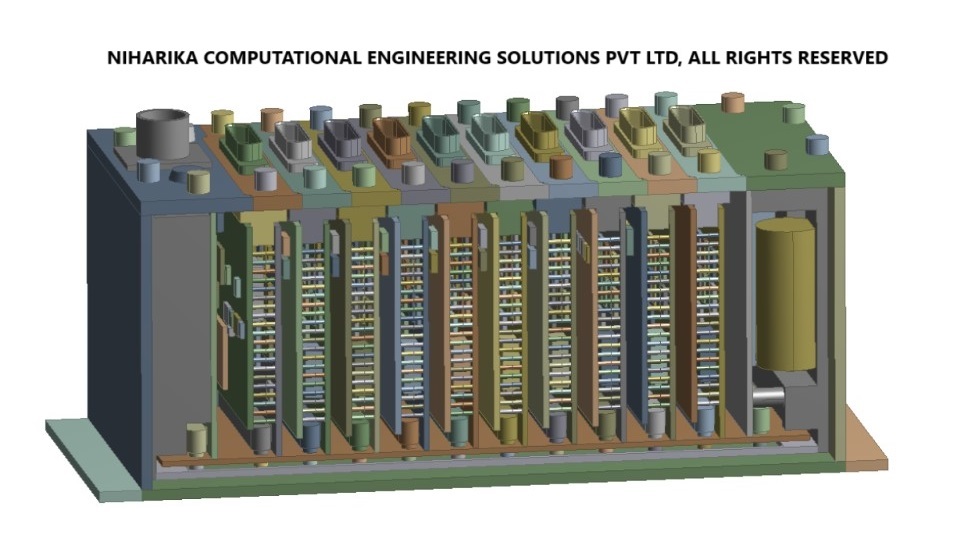

RVBF is an Inert gas-circulated, closed-loop Integrated thermal system with operating temperatures up to 1500 Deg Celsius. The Integrated thermal loop consists of a heat treatment chamber, a centrifugal blower for gas circulation, Shell and Tube Heat exchanger to achieve gas cooling, and an Electromagnetic Induction heater to reach a higher operating temperature. Controlled cooling of the job is essential to achieve the desired metallurgical structure after heat treatment. Niharika Computational Engineering Solutions Pvt Ltd (NCES) has collaborated with the client and analyzed the overall thermal performance of RVBF. We conducted transient Computational Fluid Dynamics (CFD) analysis to analyze the cooling of the job during the cooling cycle. Our CFD analysis process is validated with the help of experimental data obtained from the existing RVBF unit, which is of slightly lower capacity. Read MoreCFD analysis of Digital aircraft engine controller-FADEC

FADEC is a computer-managed aircraft ignition and engine control system used in modern commercial and military aircraft to control all aspects of engine performance digitally. Our client is a Government of India-approved Aerospace and Defense R&D unit. Read More

FEM analysis for Telemetry Flight Test Instrumentation

PCAMI-1000 is an Airborne ruggedized Instrumentation System that handles excitation, attenuation, signal conditioning, data, embedded video and audio acquisition, encoding, operating numerous buses such as MIL 1553 and Arinc, and onboard data recording and data transmission with chassis of varied slot capacities such as 3, 6, 9 and 13 slots. Read More

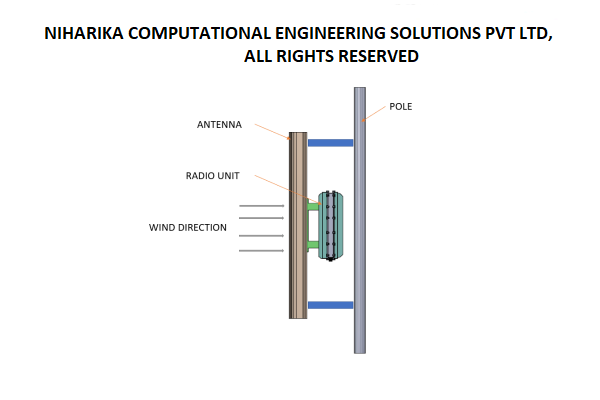

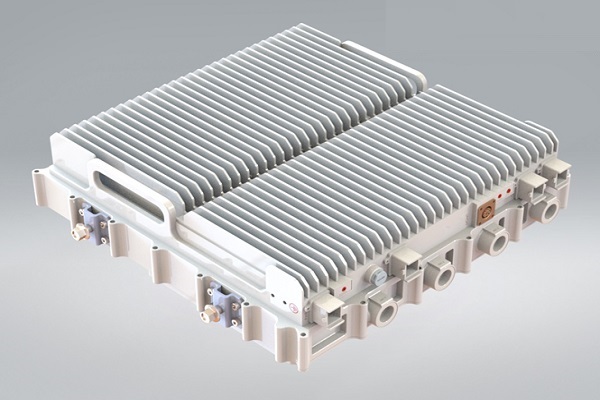

CFD analysis of Multi Band Remote Radio Unit

The advent of 5G technology has brought about unprecedented advancements in wireless communications, enabling faster speeds, lower latency, and increased capacity. These advancements are associated with higher power consumption and increased heat generation in the 5G Remote Radio units.Increasing data rates and network densification require radio units to process larger volumes of data, leading to higher power consumption and heat generation. Environmental factors such as ambient temperature, humidity, and exposure to direct sunlight also impact the thermal aspects of the radio units. Read More