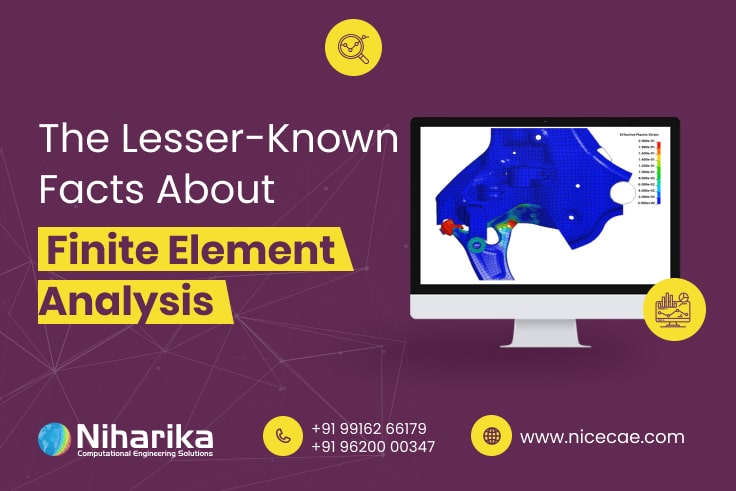

The electronics industry is rapidly advancing with new technologies emerging almost daily. However, the journey from concept to market-ready product is full of obstacles. How do engineers ensure that designs are innovative and reliable? This is where Finite Element Analysis (FEA) comes into play as a game-changer.

FEA consulting services empower manufacturers to break barriers and design the most innovative electronic systems, with outstanding performance and durability. It simulates real-world conditions in the design process and is a foundation for some of the groundbreaking advances.

The Growing Role of FEA in Electronics

Todays electronic devices must be smaller, faster, and more durable than their predecessors. This is a very challenging demand to meet. The engineers who have to design such electronic devices are plagued by problems like thermal management, structural integrity, and resistance to vibration. But FEA consulting services can help engineers overcome these challenges. By simulating real-world conditions, FEA helps manufacturers optimize designs, identify weak points, and refine their products before production begins.

FEA is made extremely valuable as it can consider many aspects simultaneously. For example, it can simulate exactly how an electronic circuit will behave in extreme temperatures, high-frequency vibrations, or sudden shocks. This information helps engineers to make informed decisions when designing robust and reliable products.

Applications of FEA in Electronics

FEA consulting services are useful in a vast range of electronic systems. Among the most prominent ones are as follows:

a. Thermal Analysis

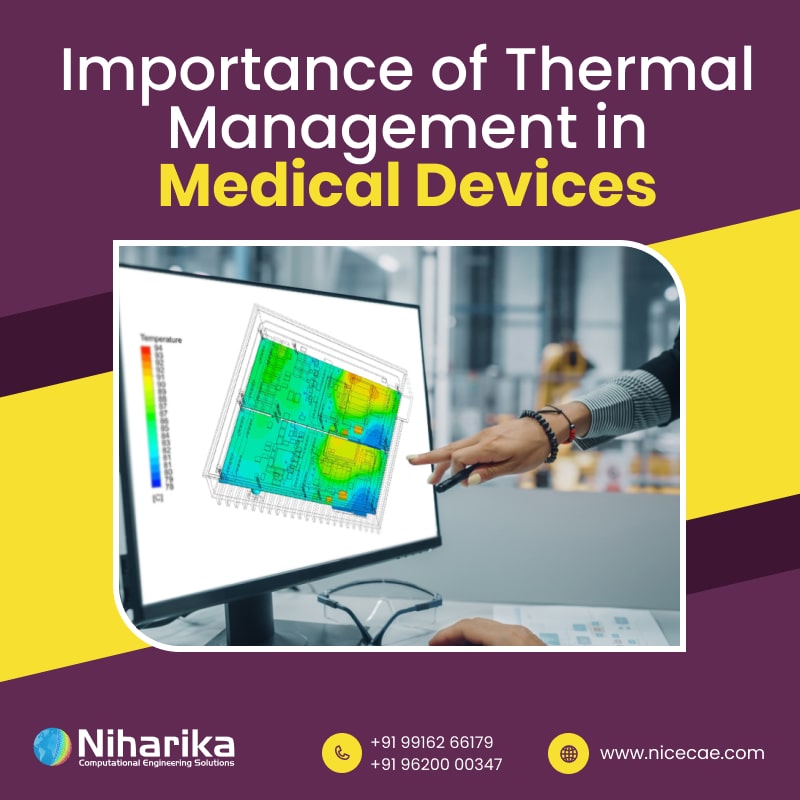

Electronics generate heat during operation. In cases where it is not managed well, performance may degrade, or even the electronic system may fail. FEA simulation helps designers come up with an effective cooling system, which includes heat sinks and ventilation. By predicting the temperature distribution, FEA ensures components are operating under safe thermal limits.

One of the most significant applications of FEA in electronics is in thermal management. Since devices are now more powerful and compact, there is a big concern over dissipation of heat. FEA helps engineers to visualize temperature distributions and identify hotspots that might compromise the performance or reliability of the device. This ability makes it possible for designers to optimize cooling solutions and component placement before building a physical prototype.

b. Vibration and Shock Analysis

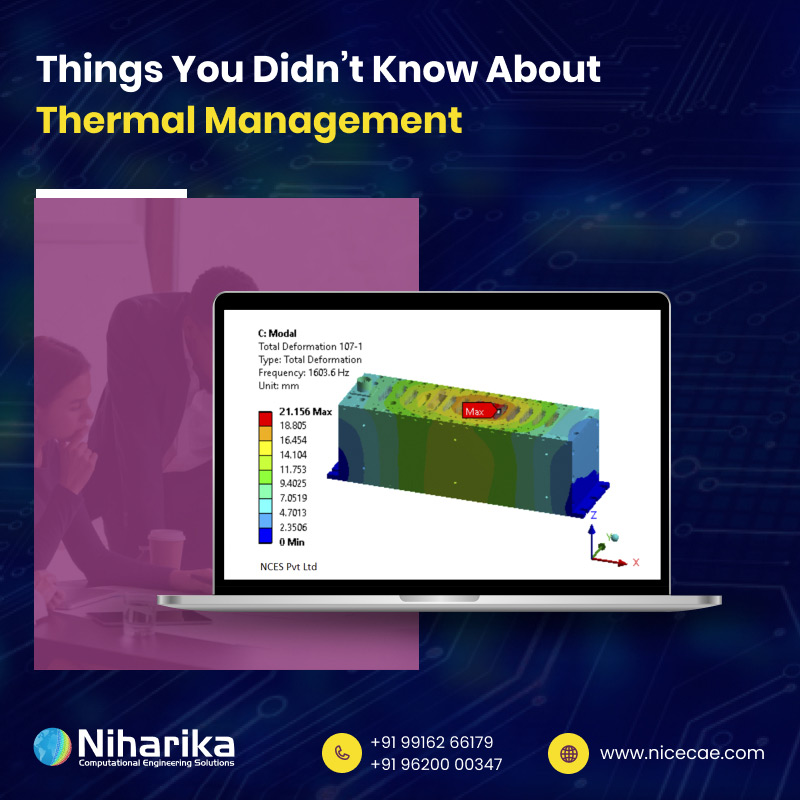

Electronic devices are often subjected to vibrations and shocks during transportation or use. FEA assesses the impact of these factors on the performance and durability of the device. For instance, modal and random vibration analyses can identify the frequencies that could cause damage so that engineers can reinforce the designs.

c. Structural Analysis and Reliability

The impact of FEA also extends beyond just thermal analysis. This includes structural analysis that helps determine how electronic components would respond under mechanical stress, vibration, and shock. This can be particularly important to mobile devices and automotive electronics in aerospace applications where these products must have withstood such environmental conditions. Engineers can also simulate drop tests, vibration scenarios, and even thermal cycling.

d. Circuit Board Design Revolution

FEA has revolutionized circuit board design. Now, engineers can analyze signal integrity, power distribution, and electromagnetic interference at the board level. This is one of the main ways to spot possible problems at the early design stages, avoiding expensive redesigns and improving product performance in general.

e. Semiconductor Manufacturing Enhancement

The semiconductor industry has adopted FEA as a fundamental tool in chip design. The thermal and mechanical stresses that arise during fabrication can be simulated to optimize manufacturing processes, thus improving yield rates and reducing defects in increasingly complex semiconductor devices.

f. Integration with Advanced Simulation Tools

FEA can be combined with other simulation tools to provide powerful design ecosystems. When paired with computational fluid dynamics and electromagnetic simulation, the multiphysics analysis becomes possible, and engineers can grasp the complete behavior of electronic systems, leading to much more reliable and efficient designs.

g. Democratization through Cloud Computing

FEA has been more accessible with cloud computing. For small and medium-sized companies, it can gain access to highly powerful simulation capabilities without any need for a high infrastructural investment. The democratization of technology has brought more rapid innovation into the electronics industry.

h. Real-World Applications

FEA has a rich array of real-world applications in the field of electronics. Consumer electronics firms use it to create thinner, more rugged products. Automobile companies apply FEA for the assurance that electronic systems can survive years of vibration and temperature cycling. Aerospace firms rely on it to validate critical electronic systems.

Looking forward, FEA will increasingly be involved in emerging technologies. Quantum computing hardware, advanced sensors, and Internet of Things devices all depend on FEA simulation. Artificial intelligence will continue to evolve, making FEA consulting services even more sophisticated, predictive, and capable of streamlining the design process even further.

Conclusion

FEA fundamentally changed the nature of designing and manufacturing electronics: it has made development cycles much shorter and more cost-effective and opened innovation avenues that previously were impossible. As electronics keep evolving and permeating every phase of our life, FEA consulting services will continue to be an indispensable tool for moving the boundaries in electronic design and manufacturing.

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)